The Evolution of Warehousing with Joe Oliaro

The Logistics of Logistics

AUGUST 23, 2023

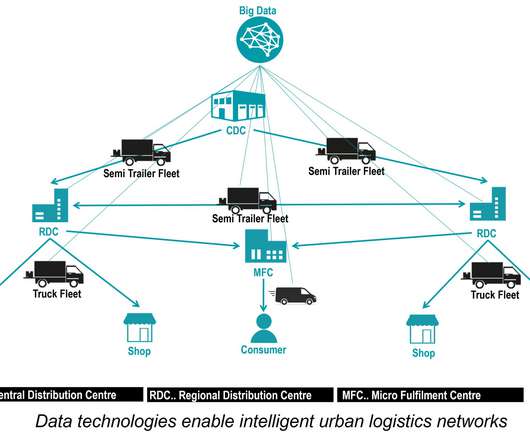

Joe Oliaro and Joe Lynch discuss the evolution of warehousing. From warehousing and distribution to transportation and fulfillment, Wagner Logistics offers a seamless and integrated solution that meets the unique needs of each client. Their services include warehousing, distribution, transportation, and fulfillment.

Let's personalize your content