Inventory Management vs. Warehouse Management

The Logistics of Logistics

FEBRUARY 11, 2022

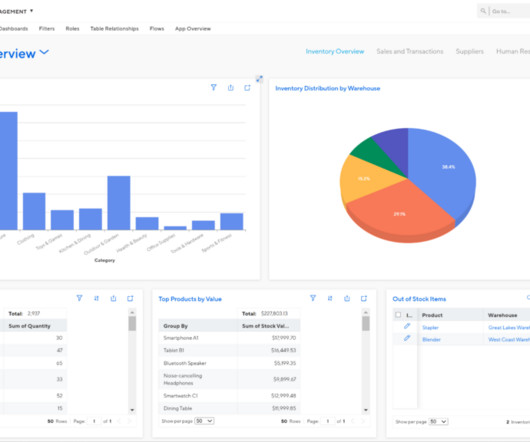

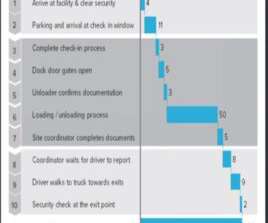

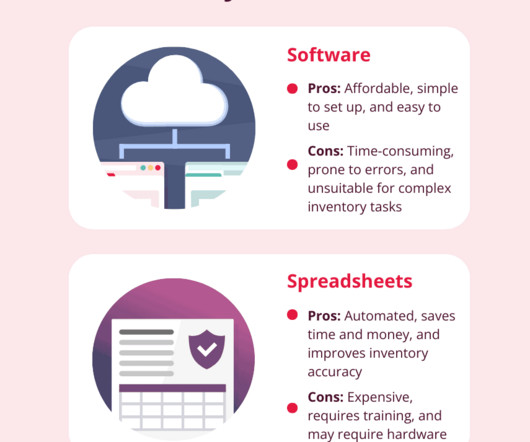

Inventory Management vs. Warehouse Management. Original article: Inventory Management vs. Warehouse Management. That may be because a company might already have an inventory system and wonders what additional capabilities they will get with a new WMS. Inventory Management vs Warehouse Management: Main Differences.

Let's personalize your content