Top 5 Demand-driven Replenishment Planning Best Practices for Retailers

In today’s market, retailers face immense challenges across the entire length of their supply chains, ranging from rapidly fluctuating customer preferences and demand patterns to supply uncertainties, extended lead times, and constantly increasing customer expectations.

As a result, inventory management across offline, wholesale, and online stores can be challenging.

Particularly in light of the ever-mounting pressure for rapid order fulfillment, there is an urgent need to rethink, improve, and streamline current retail replenishment strategies.

Though there have been numerous advancements in supply chain technologies, inventory replenishment remains an overlooked area in end-to-end operational management.

Top Effective Retail Replenishment Planning Methods

The first step toward finalizing a great supply chain replenishment strategy is determining demand. For effective demand management, it is crucial that inventory replenishment is perfectly aligned with demand.

There are several methods to do this, the top three being:

- Day/wave demand replenishment, where only the stock required for one day or wave is moved forward to picking locations. This is a useful method when managing inventory consisting of slow-moving SKUs.

- Top-off/lean time replenishment, where warehouses are filled to capacity during down time. This approach is effective for warehouses that have short picking windows, which usually means that they house high-demand, fast-moving SKUs.

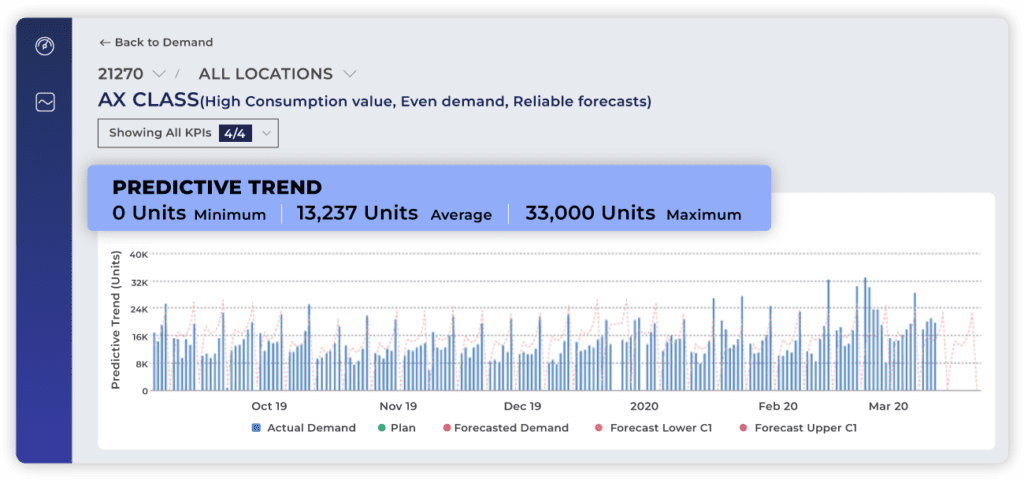

- Opportunistic replenishment, where the inventory that is required for the near term is moved out to picking locations. This approach is aimed at increasing productivity by minimizing the number of times inventory has to be replenished, and is by far the most effective method of replenishment as it is driven by demand. However, successful opportunistic replenishment relies heavily on accurate demand forecasting.

What are the Best Practices for Retail Replenishment Planning?

Building out an effective inventory replenishment strategy involves factoring in a number of considerations. Here are five key factors to keep in mind.

1. Don’t Forget to Consider External Data

External data provides retailers with a much better understanding of customer demand than simply analyzing sales data. This also allows retailers to pivot their product mix and inventory replenishment to effectively cater to continuously changing demand.

Factoring in various types of data such as seasonality, price changes, promotion schedules, and weather attributes exposes correlations that explain demand shifts.

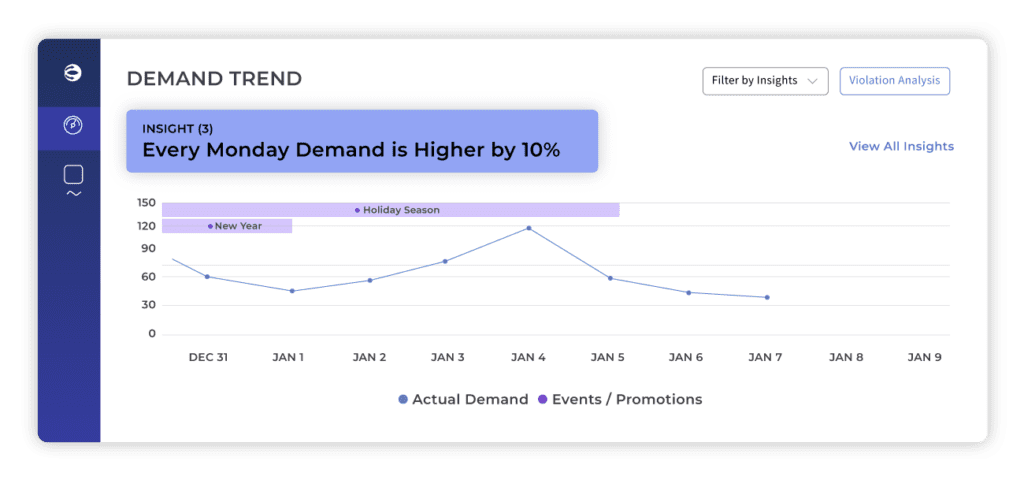

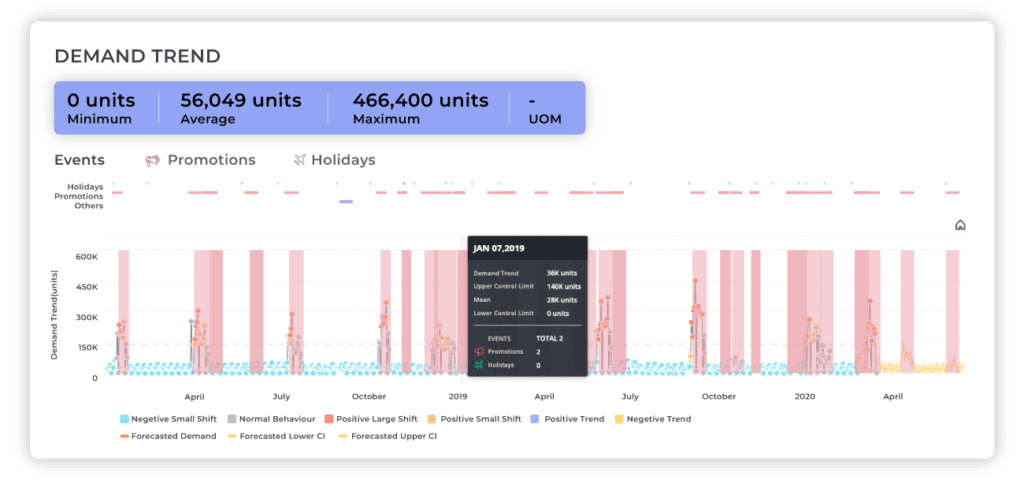

Thus, leveraging an AI/ML demand sensing platform to analyze sales data in the context of external demand influencers can help retailers accurately identify real-time changes in demand, revenue, and market share – and also the triggers for them, which in turn helps create a strategic plan to fulfill demand.

2. Load and Test Events Impact

Leverage data about future planned events, holidays, cyclical and seasonal shifts, as well as business infrastructure changes (store opening and closing schedules, etc.) to predict demand trends and recommend ideal inventory levels to support optimal distribution, while setting realistic production targets to meet market needs.

3. Build Agility into your Replenishment Strategy

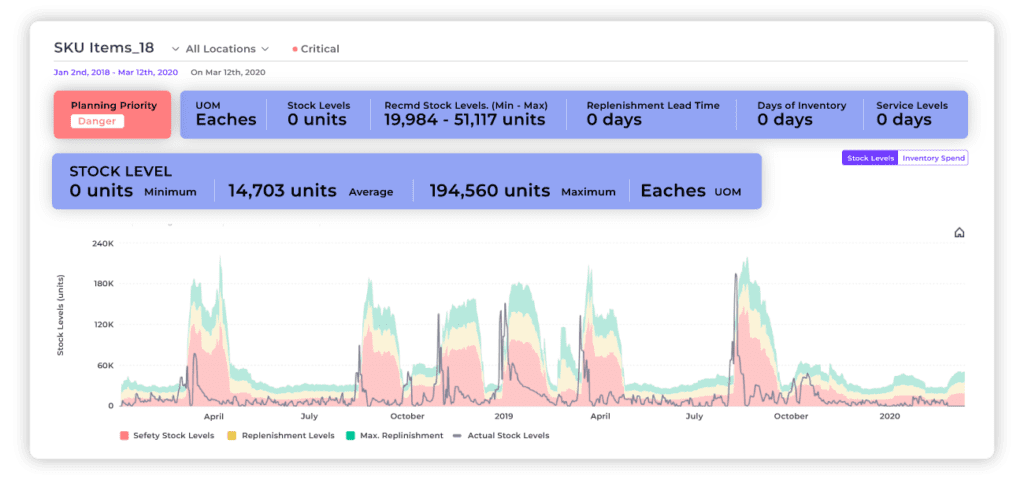

Key to adopting a demand-driven approach to demand fulfillment is ensuring the agility to respond to changes in demand – in real time. This means minimal over-ordering or under-ordering, and having just the right amount of inventory necessary to fulfill demand at all times.

Both allocation and distribution should be focused on creating a perfect pull, and removing any unnecessary moves to get products to where they are needed – on-time and in-full (OTIF) – so you never miss a sale.

The health of supply and demand signals should also be dynamically factored into inventory buffers in order to avoid flow disruptions.

4. Automate Re-ordering

An effective warehouse management system (WMS) is one that maintains a steady flow of inventory. One way to achieve this is through automated triggers, which allow retailers to set thresholds for re-ordering.

This minimizes the chance of backorders or stockouts, even when sales volume peaks unexpectedly.

5. Automate Picking to Enhance Accuracy

Picking is closely linked with replenishment, which means that any issues during the picking process can negatively affect replenishment. Automating picking can reduce order fulfillment errors, which in turn helps streamline replenishment.

6. Prioritize Replenishing Fast-moving Inventory Immediately on Receipt

When dealing with inventory that has backorders, it is a good idea to replenish it directly from the receiving dock to forward picking locations.

This minimizes unnecessary storage, and also eliminates the need to replenish again later.

7. Create a Picture of True Demand

This should be used for evaluating lost sales opportunities, and to set replenishment and distribution targets to create a perfect pull system. It also helps identify insights that drive improvements and deliver the maximum value to the financial bottom line.

Prioritizing Retail Inventory Replenishment in an Uncertain Economy

Replenishment remains a key factor in differentiating demand fulfillment, as it sets the benchmark for world-class customer experience. Retailers who leverage intelligent technologies to minimize errors and optimize processes when replenishing inventory are the ones who are best-equipped to meet – and exceed – customer expectations.

Given the economic and supply chain uncertainties inherent in today’s business world, optimizing inventory replenishment goes a long way toward driving sustained, cost-effective revenue growth.

However, while many businesses are effective at capturing allocation and replenishment data, they are unable to leverage it for the necessary insights that allow inventory planners to make intelligent decisions on the turn of a dime.

The key to that lies in the right technology.

Sign up for a demo today to see it in action – firsthand.