Lessons in Process Change from a Supply Chain Expert

As a supply chain subject matter expert, I have worked for companies of all sizes and within various industries. If one thing is for sure, it is that process change in supply chain can be hard, but it’s a constant, and every business faces making tough decisions and implementing change at some point.

When it comes to process change in supply chain and ensuring that decisions made from the top are implemented throughout the entire business – from logistics to warehouse operations, inventory management to manufacturing – these are a few of my key takeaways and lessons learned.

Triggers for Change

Mergers, acquisitions, divestures, new product launches, end-of-product lifecycle, end-of-product exclusivity, or even a personnel departure – these are all examples of triggers that can prompt change and impact how the company operates. As such, an assessment to determine if the company is prepared for those changes is needed.

Depending on the type of change, the company may not have the right sized team(s) or team members with the needed skills. Are the current processes right sized and fit for purpose? These pose interesting questions for the executive team members to consider.

Take, for example, getting a new partner. With milestone payments, this might be wonderful for the P&L, but the payments may be at risk if tactical execution is not compliant with the contractual obligations of the agreement(s). If the company is moving into an area that is not considered core competencies for the company, there may be a steep learning curve to understand how to operate in the new space. Will the company be a contract manufacturer for the first time? What about adding the complexity of a co-development or co-marketing relationship?

Remembering you have a customer with a joint vision, collaboration with the end goal in view is essential. Each partner has different responsibilities and expectations in a new relationship, and that impacts how we execute our standard ways of working. Internal processes provide direction ensuring consistent reproducible execution, and they need to be revisited.

Process Change

If you have been in industry long enough, you may have experienced, or been affected by, one of the above triggers, or have even been part of a team asked to review the strategic change, determine its impact on the business, and create the roadmap for implementation. Perceived positive changes, such as a new product launch, are easier to manage. The assessment focuses on identifying policies, standard operating processes (SOP), metrics and key performance indicators (KPI), and reports that need to be updated to include the new asset.

SOPs will need to be reviewed to make sure the current process will work for the new product. New processes should be developed to ensure all stakeholders are aligned to the process with inputs and outputs and with the information suppliers provide and customers receive, such as when using a SIPOC. New product launches must also be on time with the previously agreed upon supply, in the right location – and this is where the pressure for flawless execution lies.

If the product is in a biopharma company, there has been a team, usually CMC (chemistry, manufacturing, and controls), in place moving the product from the pre-commercial space to the commercial space. As the product moves from research to development to clinical trials to regulatory submissions and ultimately launch, the CMC team manages all the tasks needed for successful execution. This includes having the right functional areas sitting at the table at the correct phase of the overall lifecycle. Change is managed over a defined time, with known activities to be completed. This approach allows subject matter experts to be identified or developed.

What about a business change that has a negative impact, like the end-of-product lifecycle? This could be loss of patent exclusivity or a decision to withdraw the marketing authorization. There is usually a loss of revenue, which can impact on the current level of resources in every functional area. The primary focus is right sizing the organization, then revisiting the processes by which this new organization will operate.

When processes are mapped, we’ve often seen people dependent data…data that happens to be saved on their desktops. What happens when that person leaves? Identifying the primary reference for information needed to execute processes such as forecast, purchase order numbers, part numbers, labeling, batch record release, are challenging. With a reduced team footprint, there is not time for a search and find approach to needed data. A knowledge management program helps so much with this. It informs the entire team where data is stored and what is considered the primary reference as well as maintaining a high level of data integrity.

Backwards imaging can work well here to envision the future state of the organization. The focus is on what people will be doing in the future, but we can’t predict the future, so designing an organization for a future point in time can be challenging. Is the big bang approach to right sizing the organization best for the company, or is it a phased approach? The phased approach works well to ensure quality and business support continues at a high level while allowing newly formed teams or new functional heads time to assess introduced gaps and skills needed to be developed. The downside to a phased approach is that, if not executed well, it gives the perception of never-ending chaotic change versus a culture of continuous improvement with business objectives to be met.

Identify a Change Agent

We need to find the change agents in the group and bring them along on this journey. These are the individuals who have continuous improvement in their DNA and constantly have operational excellence in their thoughts. There is little time available to spend with someone who solely abides by “what’s in the SOP,” even when those processes are not working. Change agents embrace the opportunity for improvement and excellence, even when presented with challenges or resistance.

Take an Objective Approach to Process Change

This is an emotional time for everyone – those involved in these strategic teams as well as the entire organization once final decisions are made and it’s time to roll them out. Having an outside firm lead the project delivers an objective approach with best practices and industry benchmarks providing direction. The firm conducts interviews with questions designed to keep confidentiality of the larger business change, if needed. It also learns about department responsibilities and which activities are considered “centers of excellence,” as well as how to find areas for improvement. These one-on-one discussions with employees also offer insight as to how the overall department is working and if processes are complicated or difficult to follow.

These conversations often lead to a list of processes that need to be right sized to support the future organization. If the organization is large and following many complex processes (including SOP, work instructions, forms, systems), it is not an immediate concern, but the future organization will have right sized departments that will not have the bench strength to follow these processes. The processes must be reviewed, and right sized as well.

Review Processes

Once the future vision for the organization is formulated, not finished, it is time to review the processes. If you are working in a regulated industry, the best place to start is with the applicable regulations. Refresh your memory of what the expectations are and then find the simplest way to prove compliance. With a focus on continuous improvement, review the current process documents against this new view of compliance.

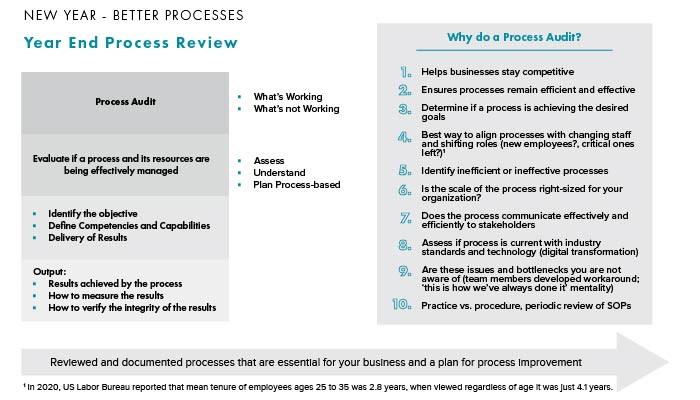

To keep processes up to date, consider an annual review, or a practice vs. procedure exercise. This approach to process change shows what is working, what is not working and if a process is achieving the desired goals or not. It also can ensure alignment with personnel changes or restructuring.

Proactive planning includes assessments of internal and external processes, influencers, customers, and partners, and creates a roadmap that ensures change can be managed to realize the new normal.

Subscribe to Clarkston's Insights

Contributions from Linda Plumley