CNC machining is also known as just machining and is used extensively in manufacturing and industrial applications. CNC machines use computerized controls and machine tools to cut layers of material to make custom parts. Whether you outsource or buy one, working with one of these machines will greatly speed up your supply chain.

How CNC Machines Are Changing Manufacturing as We Know It

Thanks to CNC machine technology, traditional manufacturing supply chains are gradually disappearing. Machine parts manufacturing companies must rely on their supply chains to obtain and transport raw materials. Once they have the raw materials they need to make a product, they will need to manufacture and distribute it to a marketer to help them sell it to potential buyers.

Although it’s complex, this is how supply chains have operated for centuries. Digital technology is altering the industry. It transforms low-performing parts of the supply chains into more efficient processes for customers and the digital manufacturing service. CNC machining and 3D printing can help businesses cut down on costs.

Companies are beginning to notice the dramatic effects of CNC machines on their production workflow. To stay ahead of the curve, they will purchase multiple preowned CNC router machines. Businesses can achieve greater flexibility, efficiency, and reliability with CNC machines.

What does the Research Say?

Transparency Market Research’s massive study on CNC machining revealed that the global CNC router market will grow significantly from 2019-to 2027.

CNC Routers Increase Productivity

Because these machines produce consistent, high-quality products, CNC routers and machines can increase factory productivity. CNC routers are highly sought-after because of how perfect the parts look to the naked eye. Companies also have to make small repairs or replace parts that are deemed unusable. As a result, more products will be made.

This reduces the chance of error and waste as well as the time required to complete a product. The 3D printing software has advanced to the point that even the most basic models can be reproduced.

CNC Sales Driven by Increased Wood Consumption Demand

Woodworking is a more popular job than ever, with many homeowners and businesses looking for woodworking jobs. Hand-made furniture is expensive. CNC technology reduces labor costs and lowers materials. This growth will be fueled by increased wood extraction in construction applications.

Metalworking will continue to be required, but woodworking is the main reason businesses are moving to CNC waterjet machines and getting rid of their old, standard metal shearing equipment.

Computer Controlled Devices Require Less Labor

Although there will be job cuts across the board in many areas, engineers and other general labor positions will still be needed to fill computer-based jobs. However, computer-controlled devices require less labor. The future job title of CNC router technician is highly sought after, but it won’t take long to acquire these qualifications or teach them.

This is a problem for an industry still in its infancy. Training can be difficult or expensive for CNC operators. This could change over the next ten years.

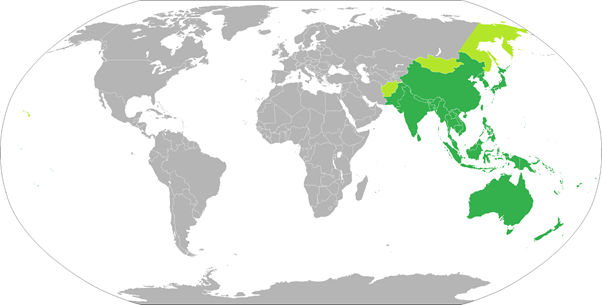

The Asia Pacific will See the Most Growth.

In the next decade, Asia Pacific will experience the greatest growth and highest demand for CNC technology. This is because of the part to the high demand for CNC technology from China, India, and Japan for automotive and industrial parts. The Asia Pacific wants to grow the automotive industry within their region. The Asia Pacific automotive industry will benefit from CNC routers and other machines.

Europe will want to also grab a large portion of this market. They will likely use the technology in the same way as the Asia Pacific, which is still an automotive industry center.

The Positive Effects of CNC Machining On Supply Chains

Research shows that CNC machining will play an important role in manufacturing over the next decade. There are several reasons companies are eager to use this technology, even though it is underutilized right now.

Lower costs

Although it will be costly to switch from a manual supply to one that is more technologically focused, this is a small price to make up for future spending. Because they can be used to produce prototyping tools at lower costs, even smaller businesses will see lower overheads.

Because they can manufacture the parts in-house, some businesses are able to produce smaller quantities of parts on-demand using a CNC machine.

High-Quality Products

Hand-making a part is difficult because of human error. Traditional machining can result in different results due to manufacturing mistakes, but CNC machines are able to avoid this problem. Because CNC machines use computer-controlled algorithms, they produce the exact same product every time. Only errors can occur when the person who wrote the algorithm is not careful or moves the equipment.

The CNC machines are equipped with an integrated inspection technology to ensure that the components meet customer standards. If an error is made, the machine will notify the company.

Faster Turn-Around Times

A CNC machine or 3D printing has the greatest advantage: they can work quickly and efficiently on a very tight schedule. Most of the processes could easily be automated using a computer. This allows them to run at lightning-fast speeds efficiently and consistently. It’s possible for your customer to have a part made in one day. You just need to make sure the parts get to your customer promptly, but unfortunately, you cannot control the mail.

Keep turn-around times down by producing complex components first and simpler components last. Both components will now arrive on time.

Traceability

While digital supply chains can be traced, traditional or manual supply chains do not. Even if the supply chain has some means to track a package, you will still need to rely on third parties to uphold their end of the bargain. Companies can track and monitor every step of the production process using digital manufacturing solutions.

A CNC machining company is able to provide information for your customer about their initial quote and how long it will take.

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram