Finally – A breakthrough alternative to spreadsheets for managing your Supply Chain

For most enterprise companies, ERP has become a foundational infrastructure technology and a cost of doing business. However, many are finding that it is not the optimal technology for Supply Chain Planning and Optimization. This has led to usage of spreadsheets to help fill in the gaps. But spreadsheets come with new challenges. Leading companies are overcoming these obstacles and finding success with an alternative that is quickly gaining adoption.

Why ERP is Not the Best Technology for Supply Chain Planning and Optimization

Supply Chain Insights, founded by well-known analyst Lora Cecere, conducts many quantitative studies and reports a couple of key trends, in their report “Three Reasons Why SAP SC Planning Is a Risk to Your Business.” The main trend is that “Forecastability (the ability to forecast a product line) has gotten worse, demand error and bias is increasing, and supply is more complex. The rhythms and cycles of business have increased. Organizations want better decisions faster. As a result, organizations struggle to match the cadence of planning to the required cadence of the business.” Companies respond to this with an “increased Dependency on Excel Spreadsheets. Despite large investments in supply chain planning, today, the global multinational is more dependent on Excel.”

SC Insights mentions a couple of reasons why SAP, the leading ERP provider and an excellent and necessary foundation for your company’s business, is not the optimal technology for Supply Chain Planning and Optimization:

- SAP Supply Chain Planning Is a Poor Supply Chain Planning and Optimization Technology.

When SAP launched APO in 2002, the optimization technologies were inferior to most best-of-breed technologies in the market. Over the years, as technology innovation has improved, staying current on supply chain planning optimization has not been a focus for SAP. As a result, the most successful SAP Supply Chain Planning implementations layer on optimization technology from a specialist vendor or University. It is an expensive workaround.

In addition, the SAP Supply Chain Planning solution is more expensive, has a longer time to value, and is harder to use than alternative solutions.

- SAP Is Discontinuing Support of the Current Supply Chain Planning Technologies.

This movement from SAP APO to SCM 7 is a redesign of supply chain planning by SAP. It bundles Integrated Business Planning, a Supply Chain Control Tower, Inventory and Demand/Supply planning into a new cloud-based architecture based on HANA. The solution is evolving, and will take time.

The rewrite extends to redefining ECC architectures. Current functionality of SAP GATP and SAP APO PPDS (production planning) will be moved into the ECC ERP frameworks. Since most companies have 5-7 ERP instances, this approach will fragment the functionality slowing the implementations and making it more difficult to build multi-tier ATP and visibility solutions.

If history is our guide, competitors’ rate of success of re-platforming a supply chain planning solution is low. I know of no time in the history of supply chain planning where a rewrite of the supply chain planning platform has been successful.

If history is our guide, competitors’ rate of success of re-platforming a supply chain planning solution is low. I know of no time in the history of supply chain planning where a rewrite of the supply chain planning platform has been successful.

In their report on “Use Cases for an Enterprise Supply Chain Modelling Platform”, Gartner summarizes it aptly by stating: “Companies often find that their current core business applications — such as enterprise resource planning (ERP) and supply chain management (SCM) systems — do not support them sufficiently in rapid modeling capabilities.”

The Challenge with Spreadsheets

With ERP not meeting their needs, planners and other decision makers resort to constructing comprehensive spreadsheets to fill the gap. The problem with spreadsheets is that they often fall short due to limitations in scalability, maintenance, complexity, and security. And, as SCInsights phrases it, “few realize that they will never be able to model complex, non-linear supply chain relationships in an Excel spreadsheet.”

What kind of tool set should you be looking for?

SC Insights and Gartner agree in their two-fold advice to:

- Stabilize your SAP investments. From SI: “Implement the SAP supply chain planning systems as a system of record. Use the SAP APO solution without the optimization engines as a system of record. Write to the SAP planning system of record from best-of-breed solutions for optimization and cognitive learning.” Gartner states: “In the market, we see several packaged applications that offer such functions, however, they are mainly designed to solve a well-defined set of problems, such as network modeling. A packaged application may not be sufficiently flexible and configurable to support the rapid development of new, experimental supply chain operating models.” As a new alternative, they suggest to use a modelling and optimization platform.

- Invest in technologies that can model your business and that your planners will use. From SI: “Supply chain planning is very industry specific and 80% fit with your business is not enough. Spend time testing and refining your planning systems.” And Gartner: “Leading companies are looking to break down barriers to speed and innovation in support of a competitive business advantage as they mature their supply chain capability. This can be achieved by utilizing configurable modeling platforms, and allowing end users to continuously develop, test, deploy and iterate new planning and optimization approaches with unprecedented speed across multiple areas and horizons of their supply chain. These platforms provide the flexibility for end users to easily configure and optimize alternative supply chain operating models, and the power to find the best possible scenarios.” McKinsey calls it “Two-speed IT”. “Our diagnostic shows that leading companies can operate both a specialized, high-speed IT capability designed to deliver rapid results and a legacy capability optimized to support traditional business operations.”

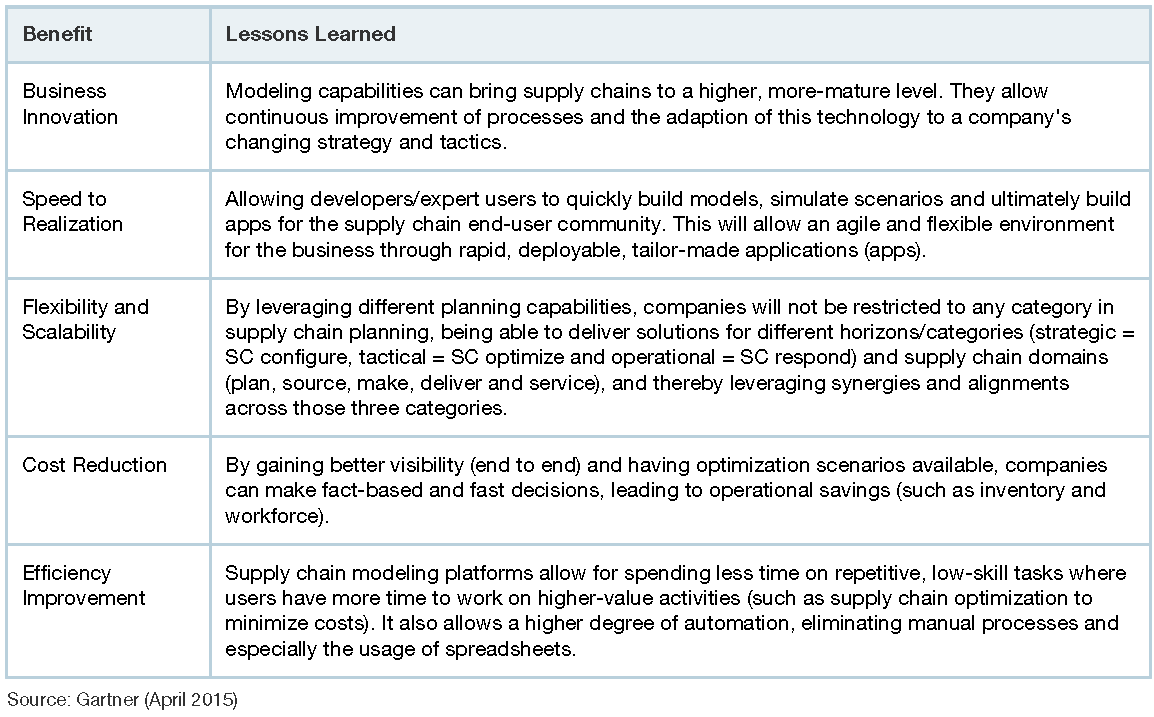

The benefits of modeling

Companies want to break new ground, to create a competitive edge through experiments and speed. Exploring new ways in the supply chain often requires rapid model development to try out new ideas, to fulfill new requirements, and to scale up to a full-blown end-user model as the idea proves valuable and needs to be implemented. What modeling uniquely brings to the table in the supply chain is the ability to generate feasible — and even the best possible — sets of actions (scenarios) based on the targets and constraints that users communicate to the system. Gartner states: “While analyzing companies’ considerations for adopting a modeling platform over a standard packaged planning system, we identified the following five major benefits and lessons learned:”

Recommendations

Gartner conducted interviews with multiple companies using a modeling & optimization platform for the report referenced above. These interviews led them to conclude that “neither ERP nor a standard packaged application in supply chain planning can provide the required speed and flexibility.” By contrast, “a modeling platform — as an additional application layer — would bring the technology to the business, instead of fitting the business into the technology, while keeping the ERP structure simple.”

Simply put, companies that are looking for solutions that provide them with a new balance between flexibility and control should consider using a modeling and optimization platform.

I do not get it – what solution exactly you proposed instead of SAP? Can you name it or give a few links to sample software?

Thanks for your comment Piotr. What we suggest is keeping SAP as a system of record and using modeling and optimization technology alongside it to answer supply chain planning questions. AIMMS is an example of such a technology. We offer off-the-shelf applications (for example to answer strategic supply chain design questions: https://www.aimms.com/applications/network-design/) and a platform to build your own models and optimization apps (https://www.aimms.com/platform/). Customers like BP have used our platform to develop apps for a variety of supply chain planning needs, from vessel scheduling to production and capacity planning. Another one of our customers is a large consumer durables brand who ships a lot of products from APAC too. We’re happy to address any other questions you may have.

Game-changing solution! AIMMS introduces a breakthrough alternative to spreadsheets for supply chain management. Appreciate the innovative approach!