Electronics Kitting and Assembly with 3PL Solutions

ModusLink Corporation

APRIL 22, 2024

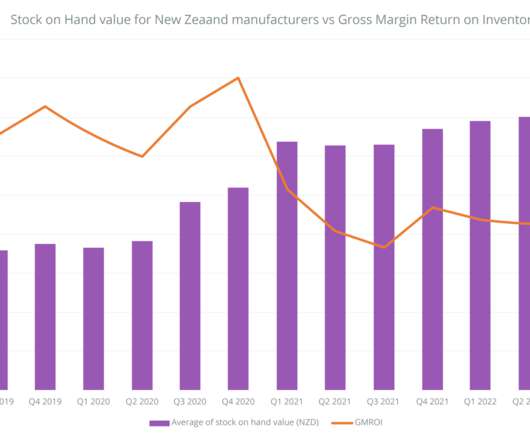

Electronics Kitting and Assembly with 3PL Solutions. By harnessing the capabilities of a global 3PL partner, companies can unlock new possibilities for efficiency, scalability, and innovation in their electronics assembly processes. End-to-end management of component procurement, inventory management, and JIT delivery.

Let's personalize your content