Save The Supply Chain Leader From Groupthink

Supply Chain Shaman

SEPTEMBER 5, 2022

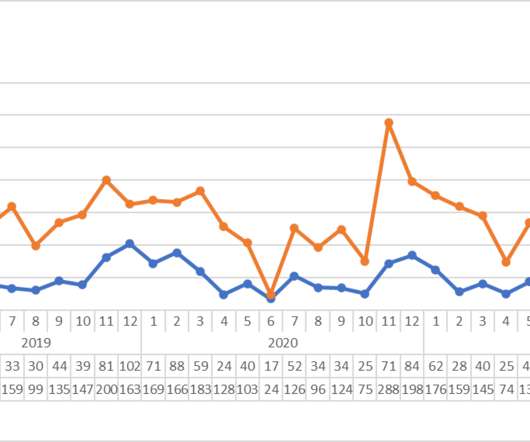

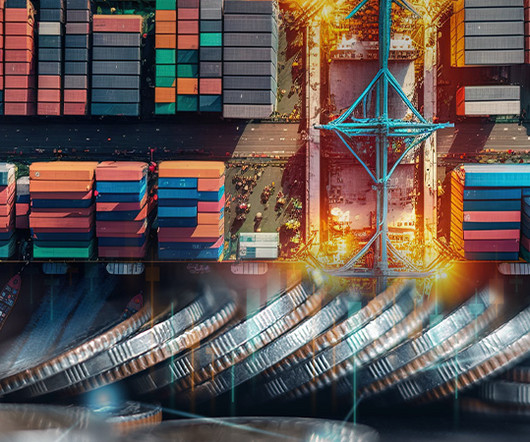

Inventory Is an Egregious Symptom of Supply Chains Gone Wrong. Today, inventory fire sales abound. Headline news included Wal-Mart, Target, Kohl’s and Macy’s struggling with inventory bloat and offering deep discounts. Business continuity continues to be a risk for many retailers and manufacturers. My take away?

Let's personalize your content