Tips for Maximizing Warehouse Space

GlobalTranz

AUGUST 31, 2018

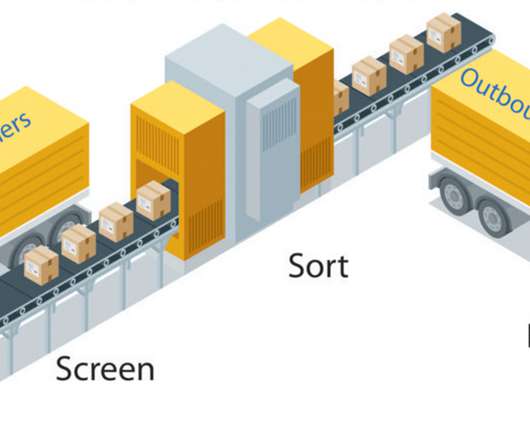

The 2018 State of Logistics Report , sponsored by 3PL Central , indicates warehousing models are evolving at a phenomenal rate. More importantly, demand for warehouse space is at an all-time high, and warehousing is still short two million workers. Optimize warehouse design. Even with 5.2 GET YOUR COPY HERE.

Let's personalize your content