Leading Inventory Attack Teams with Richard Lebovitz

The Logistics of Logistics

OCTOBER 30, 2023

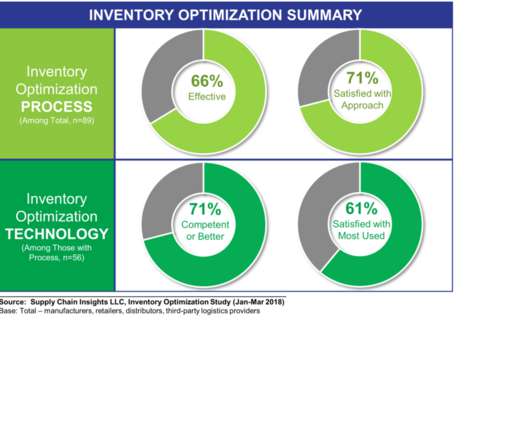

Richard Lebovitz and Joe Lynch discuss leading inventory attack teams. Richard is the CEO of LeanDNA , a purpose-built analytics platform for factory inventory optimization. About Richard Lebovitz Richard Lebovitz is the CEO of LeanDNA , a purpose-built analytics platform for factory inventory optimization. acquired by SAP).

Let's personalize your content