The Approach to Effective Freight Procurement

The Logistics & Supply Chain Management Society

OCTOBER 15, 2023

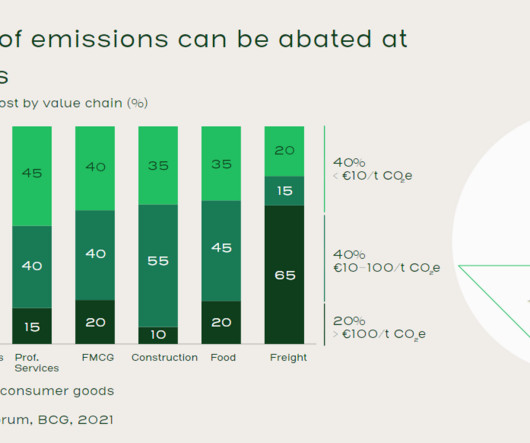

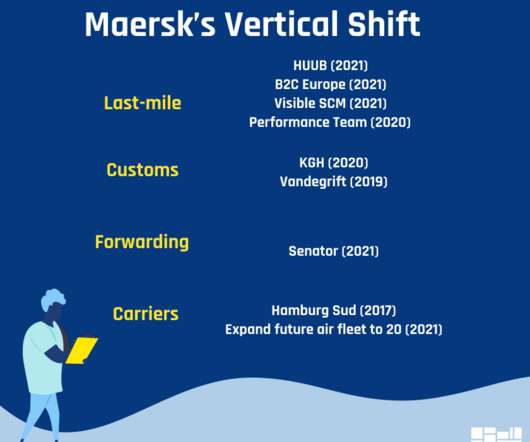

The Approach to Effective Freight Procurement by LSCMS Shippers’ Council Container shipping procurement faces a multitude of challenges shaped by global events, industry shifts, environmental mandates, and technological advancements. At the heart of it all, an effective procurement strategy remains paramount.

Let's personalize your content