2021 Logistics Outlook: Truckload Freight Market Forecast

GlobalTranz

DECEMBER 22, 2020

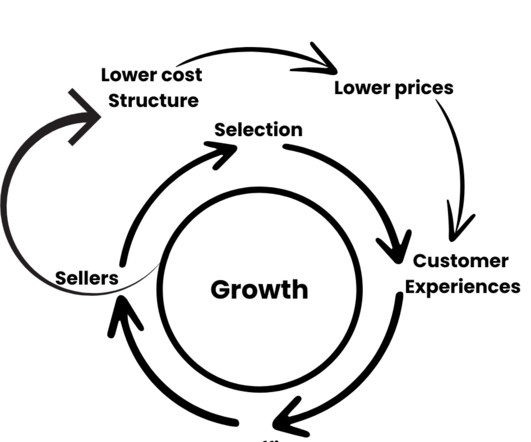

During the second half of the year, consumers shifted their spending from in-store to buying online, and sellers had to adjust their warehousing and fulfillment networks. To help shippers prepare, we will examine contributing factors that will play a significant role in the 2021 truckload freight market.

Let's personalize your content