Ocean Freight: Key Trends & Planning For Peak Season 2023

Ware2Go

JUNE 20, 2023

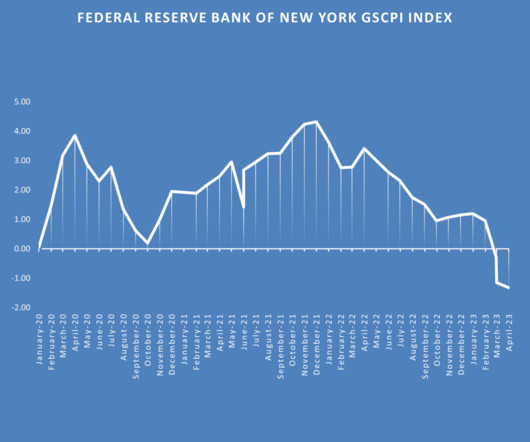

See the latest insights on ocean freight rates and other trends that fast-growing businesses should know about to plan for 2023 peak season. In this article: Ocean Freight: Key Stats & Industry News Ocean Freight Shipping: What to Watch For In 2023 Freight Shipping From China & Alternatives What Are The Current Ocean Freight Rates?

Let's personalize your content