Holiday Warehousing Challenges 2021

3PL Insights

SEPTEMBER 20, 2021

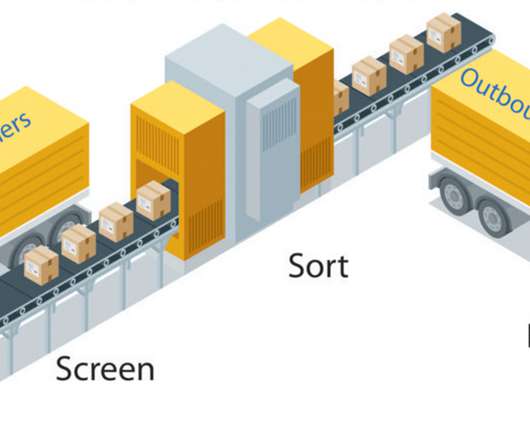

Limited Warehouse Capacity. After the shipping delays and supply shortages that were caused by COVID-19, many businesses have opted to keep more inventory on-hand in distribution centers. This leads warehouses to operate at a much higher capacity than in previous years which limits the space available for increased holiday demand.

Let's personalize your content