Supply Chain Normalcy? Think Again.

Supply Chain Shaman

APRIL 18, 2023

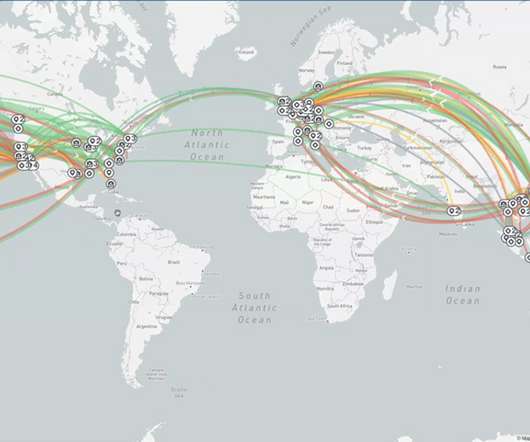

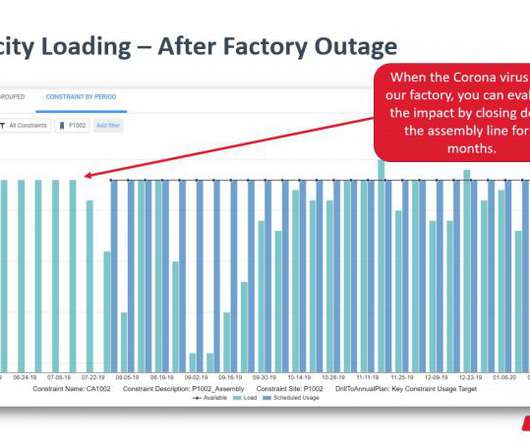

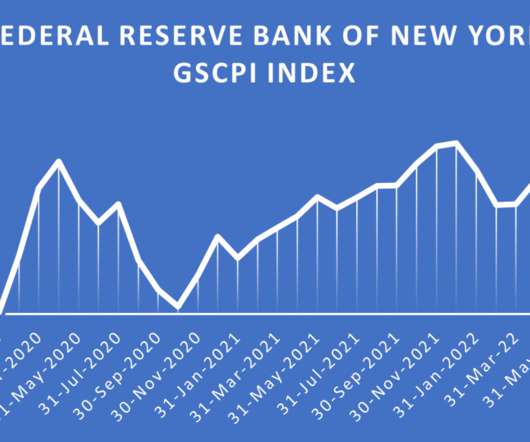

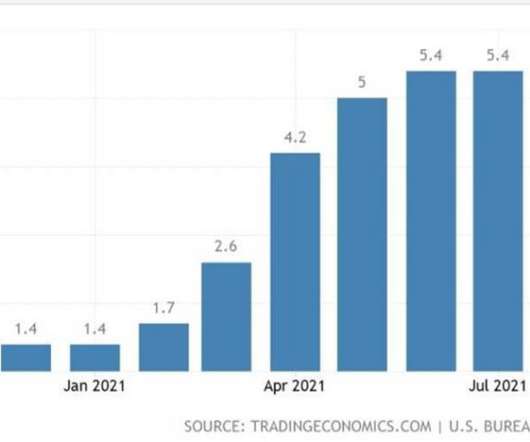

The global supply chain is built on three assumptions: rational government policy, availability of reasonably priced logistics, and low variability. In March 2023, the Global Supply Chain Pressure Index fell to the lowest level since November 2008. However, variability and global unrest is rising. Build in-market sourcing.

Let's personalize your content