When I was a teenager, I spent afternoons after school with my dad. As he lost his vision to macular degeneration, he taught me to play chess. He loved chess, and I was a reluctant participant. I played because I loved my dad, but I never was good at the game. The continual lesson to me was never underestimate the power of the pawn.

Pawn Definition: “A chess piece of the smallest size and value. A pawn moves one square forward along its file if unobstructed (or two on the first move), or one square diagonally forward when making a capture. Each player begins with eight pawns on the second row/rank and can promote a pawn to become any other piece (typically a queen) if it reaches the opponent’s end of the board. It is also used to describe a situation where a person used by others for their own purposes.”

Oxford Dictionary

A Reflection

I spoke to a past client today. The focus of the discussion was how he was used as a pawn by his past dysfunctional management team. He is no longer employed by that firm, and it hurts. He was proud of his work at the company, and made many strides to drive improvement, but was forced to leave. In our discussion, we attempted to characterize and separate his performance from system issues. Sometimes, this is a tough discussion.

He worked with an executive team of Jim, Dave, and Bill. My client attempted to have a supply chain discussion to improve flow, and his executive group just did not get it. Bill was a strong advocate of SAP ERP. His view was very transactional. Bill had his sights set on the Chief Operating Officer position and wanted to be seen as competent managing operations. He saw my client as competition. As a result, my client became a pawn to eliminate as he drove to his goal of supply chain improvement.

As I coached my ex-client, I remembered my experience in the 1980s when I was a pawn. (Yes, I am that old.) Let me tell you the story. I worked three layers down in the organization for a well-established leader in manufacturing named Dan. I did not know Dan as an individual: we had a boss/subordinate relationship. Dan’s peer was a man named Fred. Fred owned logistics and customer service for the organization. Fred and Dan did not get along. They reported to a man named Tony. Dan had a very manufacturing view and Fred focused on logistics. I was promoted to run the warehouse, and at the time, I had no experience in distribution, but was asked to run the largest distribution center in the system. The issues between Fred and Dan ran through the organizational structure.

A warehouse is the tip of the spear for dysfunction. Dan rewarded the factory on efficiency and OEE. As a result, the warehouse, supporting the factory, was always full. In contrast, Fred’s bonus was on logistics costs, so he was constantly rebidding lanes and bringing in new carriers. Dan and Fred were not aligned on the role of the distribution as it tied to supply chain excellence, and Tony was a marketing guy.

The warehouse I ran just completed a consolidation of three shipping centers. The analysis, based on network optimization assumed average loading, and did not account for the volume swings. So, I was always struggling on a daily basis to establish a feasible plan to ship 180 trucks out of 22 doors in a twenty-four-hour operation.

I was a big advocate for software improvements. Often volunteering to take a software implementation first and pilot it for the company. At the time, we attempted to implement warehouse management, but failed. In the early 1980s, warehouse management was a tough implementation due to the immaturity of the software. As a result, we did not have a perpetual inventory signal for order management. My day was spent with regular calls from order management to affirm inventory for a rush order. I would walk the pick and manually confirm inventory availability.

Fred’s first-pass tender load tendering through EDI was never based on a feasible plan, so each day, we manually reassigned 95% of the loads to carriers. The costs attributed to least-cost lane sourcing was fictional because carriers were never held accountable to pick up their loads.

I also ran three outside warehouses. Without a perpetual inventory signal, we were never synchronized on where to place customer orders. The planning was all manual.

When a guy named Gary started implementing Distribution Requirements Planning (DRP), I asked him to describe (and defend) the safety stock calculation. He could not answer my question. As a result, inventories ballooned after the DRP implementation.

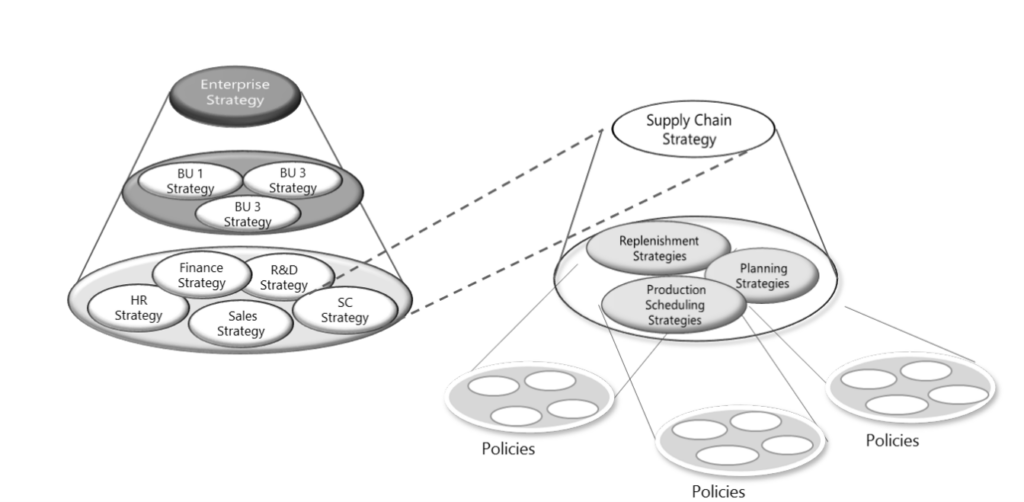

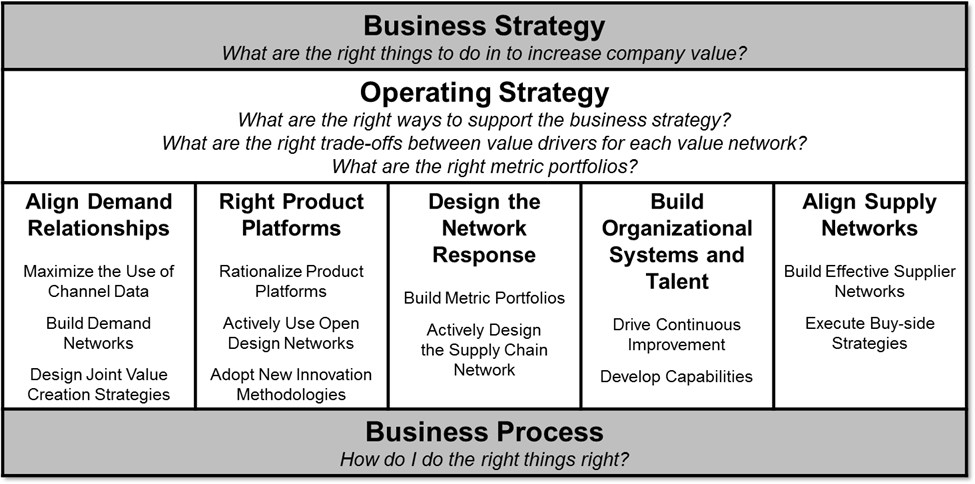

At that time, Fred started pressuring the organization on the DOI (days of inventory) levels. He wanted control of the warehouse to reduce logistics costs. His goal was to separate manufacturing and distribution inventories to improve his bonus incentives. The metrics were not aligned. The company operated on a very functional view as depicted below. Production and replenishment policies should never be distinct.

One day, when I went to work, my boss, Tim called me to his office to introduce me to the Deloitte team. Fred hired Deloitte to rationalize in-house distribution versus outsourcing to a 3PL. I was never asked or informed about the project but was asked to support it. At the time, I struggled to rationalize why a 3PL would ever make sense– the lack of inventory management and the data latency seemed like a barrier. At that time, there was no perpetual inventory signal across warehouses, and it was an issue. I also could not imagine that Fred, in a principle-based organization, would terminate the employment of much of the warehouse workforce to improve his incentives.

I worked hard to help the Deloitte team making the case that a 3PL would never make sense. The folks I worked with were junior and knew little about warehouse management. I did my best to educate.

Little did I know that Deloitte would recommend the separation of the warehouse systems and endorse logistics outsourcing based on a labor cost reduction and that most of my team would be fired. I was a pawn. The bad news is that I was not a winning pawn. I did not recognize the organizational dysfunction early enough. I fought a losing battle.

What Is Strategy?

This view was very different than the more holistic view as shown below:

In the Deloitte study, the needs of manufacturing, procurement, and logistics were not considered together. The metrics were never aligned to drive order fulfillment improvement and reduce total costs. (The reduction of functional costs in either manufacturing or logistics will often increase total costs due to the dynamic nature of the supply chain as a complex, non-linear system.) There was no network design analysis in the Deloitte study. The recommendation was made based on a labor cost reduction on an excel spreadsheet.

Be A Winning Pawn

Unfortunately, there are many teams that have Fred(s) and Dan(s). Or Dave (s), Jim(s) and Bill(s). While companies speak about moving from a functional view to more strategic alignment, it does not happen. The issue? It cannot. The thorny factors are bonus incentives, conflicting objectives, and established career paths. The Fred(s), Dan(s), Dave (s), Jim (s) and Bill (s) only know their function. They were groomed to lead their function not to drive supply chain excellence with a holistic focus. Traditional applications focused on ERP as a backbone reinforces this structural dilemma.

Cross-functional training is rare in an organization. Traditionally a logistics guy would never run a warehouse, or a manufacturing team leader be tasked to implement warehouse management. And there are many junior consultants tasked to do the bidding for the many Fred(s) of the world. In the middle, there are many pawns.

If you find yourself to be a pawn in the game, be the winning, not the losing, pawn. Remember that a pawn in chess can become another piece through perseverance to get to the last row of the board. If you find yourself be used as a pawn, take these steps:

- Don’t be a victim. Don’t dwell on the negatives. Focus on going forward by going forward. When Deloitte makes the decision that will fire your team, go forward by going forward. You have to do so. Download Taylor Swift’s song Shake-it Off and move on.

- Map the different metrics and incentives in the organization to behavior. Read the organization, and when you think you know it read it again. Look at the artifacts on the bulletin boards, the award systems and the elements of the culture. Looking deeply to understand what drives behavior. Map influence groups and gain an understanding of social connections. Don’t be politically naive. Be aware.

- Get good at the tactics of visualization, storytelling and laughter. Diffuse situations and help people to see what they cannot understand through stories and visualization. Many executives are visual learners. (Use network design and planning tools to show flow.) Do less telling and engage in more experiential activities. Avoid acronyms and supply chain jargon. Laughter is the best medicine.

- Seek first to understand. Delay judgement. Be open to the outcome. If you find yourself in a divisive moment, pull yourself up, and try to understand people’s motivations to behave the way that they do. Own your behavior to move things forward. Try to diffuse bad situations.

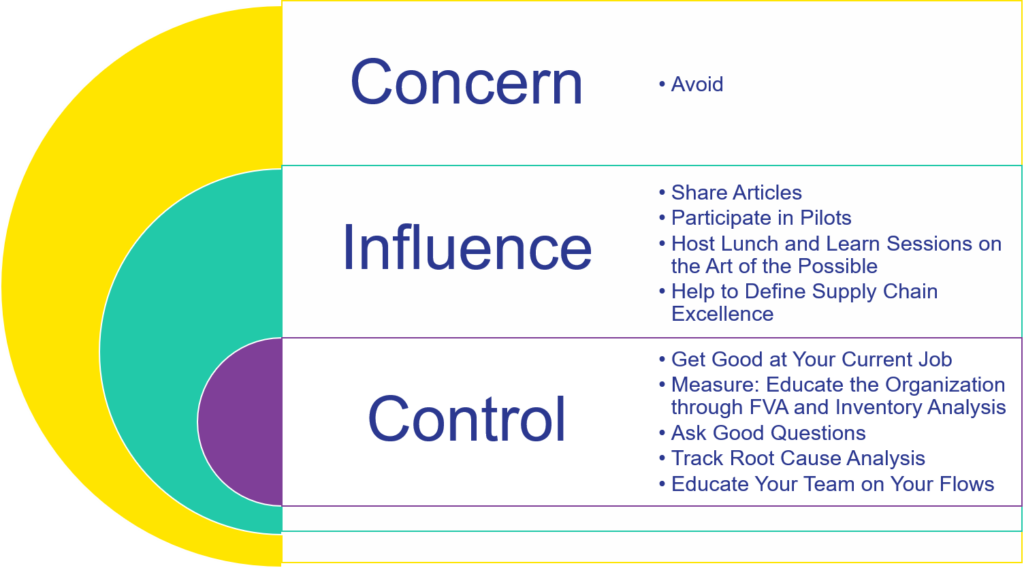

- Don’t fight losing battles. Know your circle of control and widen your circle of influence. Stay out of your circle of concern. Earn the right to be in the circle of concern only by widening your circle of influence. Widen your circle of control by getting good at your job and your circle of influence by building effective support networks within the organization. (This takes work. And, if you have a strong task orientation, you will struggle why it makes sense. Try it. Building strong networks works.)

Summary

In business, there are many pawns. Build the understanding of how to be a winning versus a losing pawn. The reason why? It just more enjoyable. And, who knows what your transformation will be when you make it to the end of the board. (Send me a text when you make it.)

What do others think? What can you share?