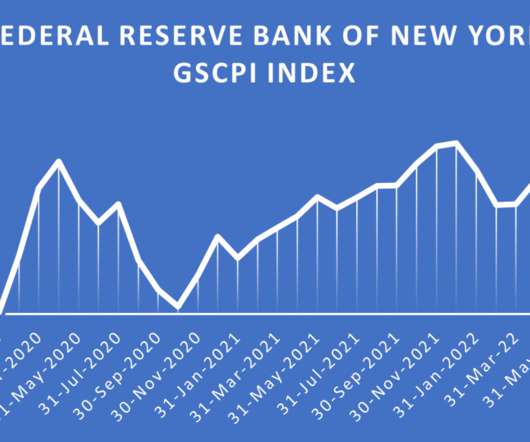

Track the Supply Chain Metrics that Really Matter

Precoro

MAY 19, 2023

According to McKinsey survey of global supply chain leaders , only 53% of respondents describe the quality of data in their supply chain planning systems as “sufficient” or “high.” By setting benchmarks for metrics, analysts can recognize unsettling trends and take preventive measures on time.

Let's personalize your content