ToolsGroup-IHL Group 2022 Retail Inventory Study Shows Diminishing Customer Loyalty Due to Out-of-Stock Concerns

ToolsGroup

SEPTEMBER 29, 2022

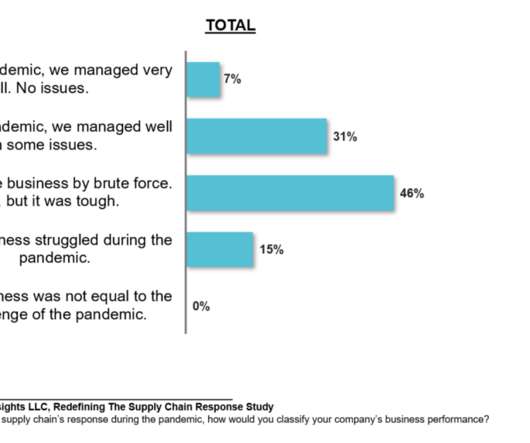

Improving inventory position can help retailers secure consumer loyalty and capture impulse spending. Across other retail sectors, customers have increased their trust in inventory availability from 1-7%. In July 2022, IHL and ToolsGroup surveyed U.S. consumer trust in retailers over the last two years as a result of out-of-stocks.

Let's personalize your content