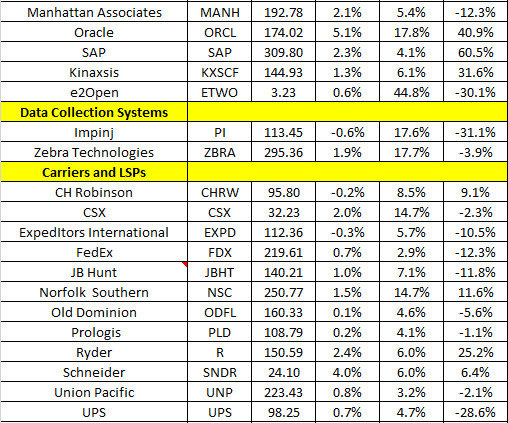

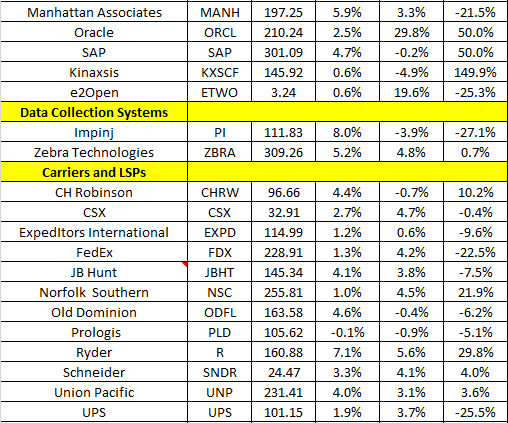

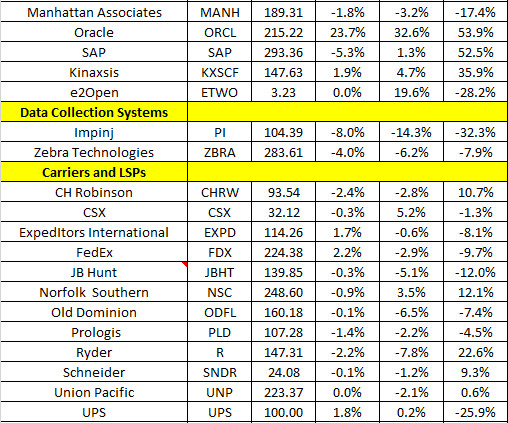

Manhattan Associates Joins a Select Group of SCM Software Vendors in the Billion Dollar Club

Logistics Viewpoints

JANUARY 29, 2025

Manhattan joins a select group of supply chain software suppliers generating over $1 billion in annual revenue. Manhattan Associates is a leader in two markets, warehouse management systems and omnichannel systems. The WMS solution optimizes productivity and throughput in distribution centers and warehouses.

Let's personalize your content