Beware the Swinging Pendulum on Supply Chain Inventory Practices

Logistics Viewpoints

FEBRUARY 3, 2022

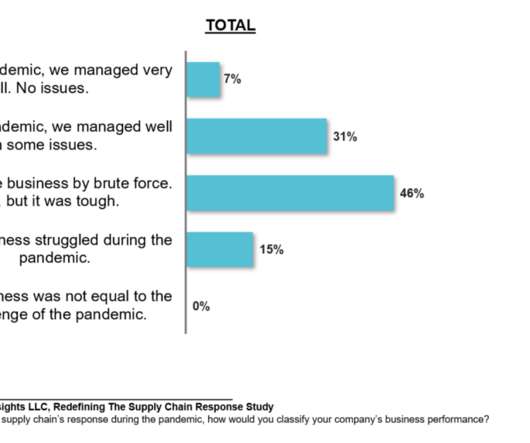

Supply shortages resulting in empty shelves or parking lots of WIP inventory represent a spectre causing supply chain leaders to reconsider supply chain inventory practices. Opinion of just-in-time (JIT) as a practice has taken a battering and inventory is rising. Is supply chain inventory the problem?

Let's personalize your content