Organizational Alignment: Overlooked, but So Important.

Supply Chain Shaman

DECEMBER 15, 2022

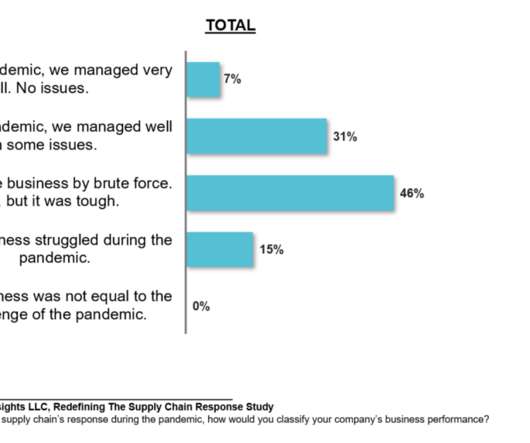

If you answer the survey, I will gladly give you a custom analysis of your organization against the peer group. The financial teams, and the Information Technology (IT) groups, did not see alignment gaps, but the supply chain teams felt them and viewed them as a critical performance issue. Functional Metrics.

Let's personalize your content