Infrastructure Planning Guidelines for Supply Chain!

Supply Chain Game Changer

OCTOBER 2, 2020

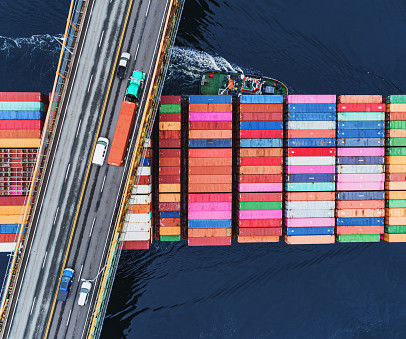

Whether you are planning to start from scratch or looking to revamp the existing infrastructure for your business, here are some guidelines to help with your infrastructure planning. Enhancing supply chain operations is all about collaboration between various operations, including manufacturing, procurement, logistics, sales, and finance.

Let's personalize your content