How To Jump

Supply Chain Shaman

APRIL 16, 2024

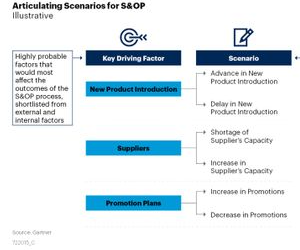

Yes, there is a great opportunity, but the question is how to jump. How to get started? Technology providers focus on serving the planner, but I find that they are blind to the larger requirements of how to serve the organization better. How do I improve the plan? in inventory value. Guess what?

Let's personalize your content