Realizing the Value of Supply Chain Optimization for Tire Manufacturing

DELMIA Quintiq

NOVEMBER 17, 2020

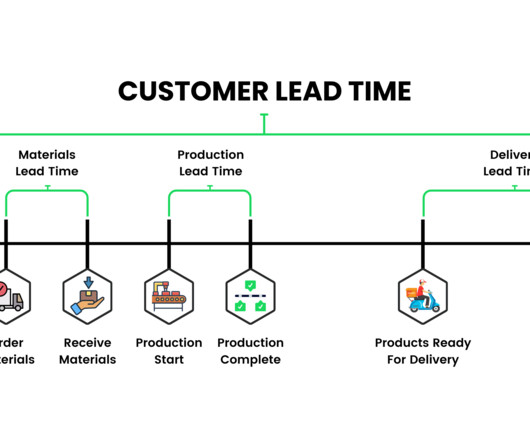

New technologies revolutionizing transportation are creating tremendous opportunities but also unprecedented challenges for tire manufacturers. Supply chain optimization is essential to achieve this and can help tire manufacturing companies deliver significant reductions in supply chain costs and improvements in service levels.

Let's personalize your content