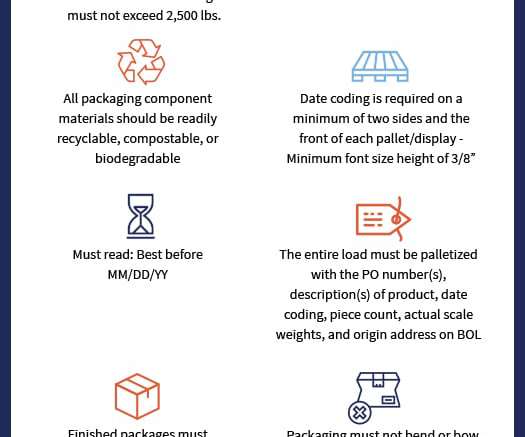

How to Reduce Product Damage During Shipping

GlobalTranz

SEPTEMBER 15, 2017

Editor's Note: Today's blog is from Cindy Banker with ProCorr Display and Packaging who is bringing us some great insight on how to reduce product damage. If you are a product manufacturer, you know all too well the perils of shipping products from your factory or warehouse to a DC or retailer. Trucking Logistics.

Let's personalize your content