Procurement culture: challenging the old, developing the new

One of the biggest challenges facing the indirect procurement industry today is digitalization. Here Costanza Campi, Senior Vice President for Global Procurement at RS Integrated Supply, shares her insights into this issue and explains why revenue dependency makes digital transformation within indirect procurement so critical.

Will procurement roles continue to exist?

My daughter said to me, mummy, you have a good job. You talk all day, you travel and go places, and you seem to buy lots of things without using any of your own money, so I want to do your job when I’m older. The big question is whether procurement roles like mine will still be around in years to come. With technology ramping up so fast, what will we do when Artificial Intelligence (AI) replaces us?

A procurement transformation

Let’s start where we are now, with different levels of maturity within procurement and organizations moving from reactive to proactive to predictive.

At a previous company where I was procurement manager, for example, the senior director for the fragrance category came to me saying the bottle for a new perfume must be a particular shape. I had a clear task as to what to buy, but there was no external perspective about what existing capability was out there to produce that bottle or what constraints existed in terms of supply chain or so on.

To move from this reactive approach to being proactive, what we did was ask the supplier for their view about what a fragrance bottle would look like if, to improve supply chain agility and costs, we were to optimize design based on the manufacturing facility. It is shifting from a reactive space where we want something and then go out to find it in action to look at what’s happening out there. This is the way to design items so the manufacturer has the right bottle when we need it and at the right price.

Digital technologies and predictive procurement

Part of the transformative power of digital technologies comes from their automation and self-serve capabilities. When an engineer works on a line, they no longer need to go off to buy the parts required. Now we have the digital capability to offer an e-catalog that is like a consumer experience so the engineer can access whatever they need, when they need it, via their mobile phone.

The next move is into predictive procurement. With today’s Industrial Internet of Things (IIoT) technology, you can have a sensor on every piece of equipment and the data this generates will tell you when you are likely to have a failure. This will reduce your downtime because rather than having a potentially line-stopping breakdown for which you don’t have the right part available, you’ll know a machine is likely to break down in X number of cycles, allowing you to forecast what you’re going to need and have it there ready.

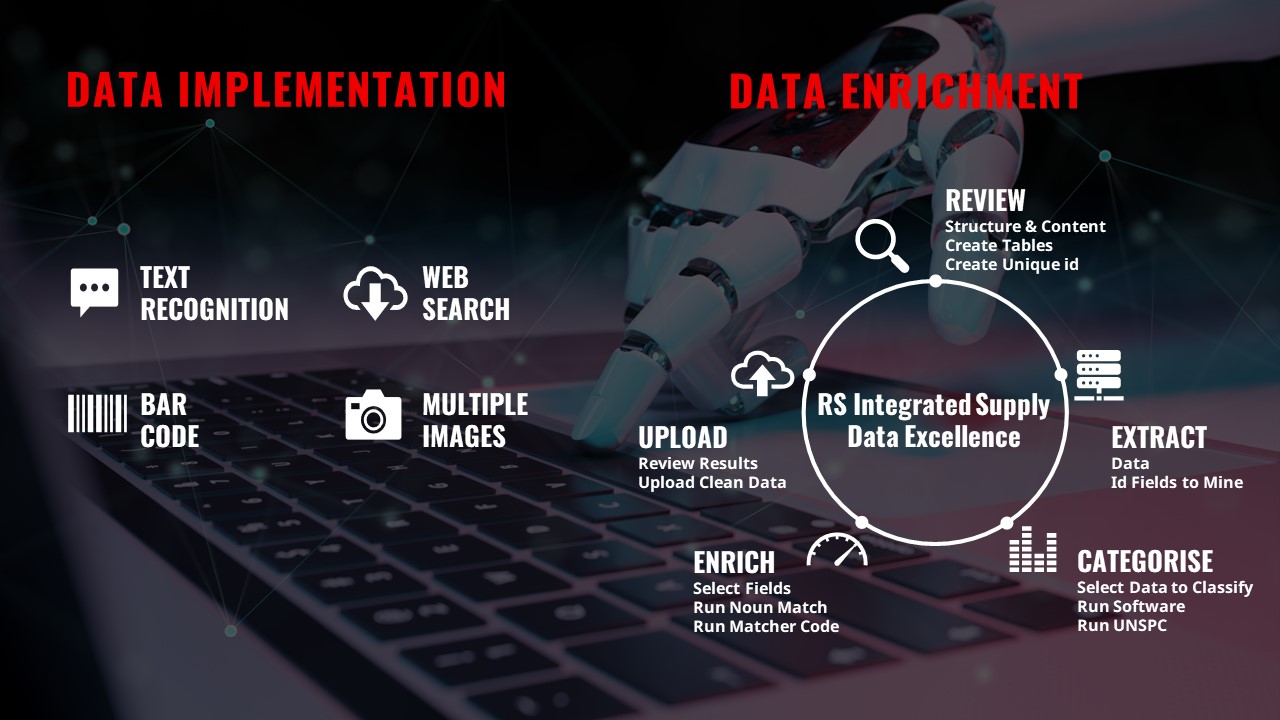

To make the most of digitalization, the data you are working with needs to be accurate. Often it is not. At RS Integrated Supply, for instance, one of our pharmaceutical clients had a data accuracy level of less than 15%. To help them move from reactive to proactive and predictive procurement, and optimize the procurement process, we needed to improve this figure. We did this by cleaning the available data, increasing its accuracy to more than 70%.

Figure 1: Data Implementation vs. Data Enhancement

A new procurement culture

Predictive procurement, once in place, eliminates the transactional element of procurement roles. This takes us back to the initial question: what will we do when AI replaces us? However, this is not necessarily a threat. On the contrary, it can be an opportunity.

For procurement professionals, being relieved of the onerous task of managing transactions provides an opportunity to develop new skills and capabilities that better meet the needs of the organizations where we work. For the procurement industry more broadly, stepping away from a transactional role is an opportunity to evolve and develop further as a strategic partner that can have a positive impact on wider business goals.

To achieve this, our organizations need a culture where we are all clear about the why, not just the what and the how of our roles. As digital transformation reshapes our working lives, we need to create a compelling vision of the contribution that procurement can continue to make. This vision must include people and understand their perspectives. What does this shift from a transactional function to a strategic one mean, for example, for the long-serving MRO (maintenance, repair, and operations) stores manager? Their role may need to be different, but their acumen and experience remains just as vital.

The cost of failure

There has always been a far greater focus on direct procurement, the materials that go into finished products, compared to indirect procurement, of which MRO materials are a part. While this is understandable given the size of the budgets involved, it also means indirect procurement is an area that remains very reactive. It’s playing catch up.

Transforming MRO through digitalization is not, however, about unit cost. It is not about an engineer thinking they’ve got a bargain. How much is being saved when a highly trained engineer spends time looking for a low value spare part? Really, it is about revenue dependency. An individual part may cost next to nothing, but if you do not have that part available when a line goes down, how much does that downtime cost you? What is at stake in terms of lost production?

The goal, therefore, is to create a noiseless supply chain where everything runs smoothly, and you have what you need when you need it. That is the main objective – and digital transformation, including AI, can help you to achieve it.

Author

COSTI CAMPI, SENIOR VICE PRESIDENT, GLOBAL PROCUREMENT, RS INTEGRATED SUPPLY

Costi is a highly accomplished, dynamic, visionary business and procurement professional who combines strong strategic leadership with hands-on execution. With over 20 years of experience, she has a proven record of optimizing global sourcing strategies across industries such as pharmaceutical, chemical and FMCG. She holds a master’s degree in Physic Chemistry and is fluent in Italian and English with basic knowledge of German and French.