Procurement on the Thames: Ivalua’s London Summer Symposium

ivalua

JUNE 26, 2023

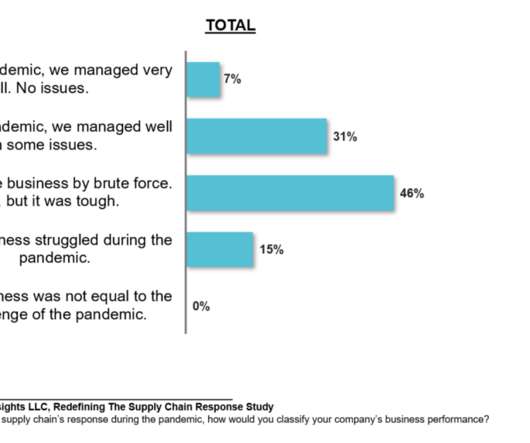

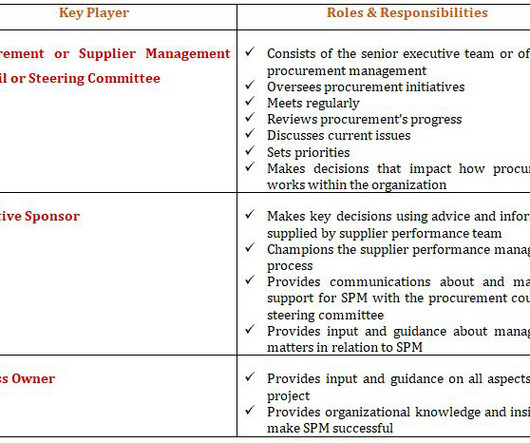

Blog » Procurement on the Thames: Ivalua’s London Summer Symposium June 26, 2023 | | Thought Leadership by Eloise Barnum As businesses navigate through supply chain disruptions, high inflation, and sustainability initiatives, procurement, and supplier management has taken center stage in driving change.

Let's personalize your content