ZF’s Transition from Lean to Supply Chain Resilience

Logistics Viewpoints

OCTOBER 31, 2022

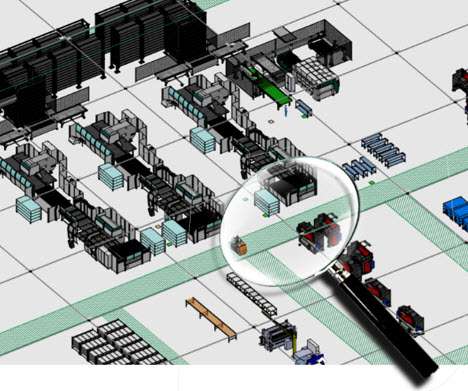

Among other things, ZF manufactures electrified powertrains, car chassis technology, active and passive safety systems, and advanced driver assistance systems. ZF offers product and software solutions for established vehicle manufacturers and newly emerging transport and mobility service providers. at the ZF Group.

Let's personalize your content