This week, I spoke to John. As a supply chain leader, he is struggling how to dance in the ring of fire. You may also be facing the same issue. Let me explain.

What Is The Ring of Fire?

The ring of fire is corporate politics at the executive level on supply chain performance. Each executive has a different perspective on the definition of supply chain excellence, but they are never discussed and aligned. The CFO believes that the supply chain should be efficient, the CIO wants to standardize on fewer applications, and the Chief Operating Officer wants to improve customer reliability, but the team does not realize that their leadership puts the supply chain leader in the crosshairs of the executive team.

Let’s focus first on John. His organization purchased an advanced planning technology from well-known best of breed provider, and the implementation should have been successful, but it was not. As a result, demand planning is largely manual, inventory management is a series of manual inputs, and production planning is via spreadsheet. (BTW, John’s situation is more common that most people acknowledge.)

The focus by Anne, the CIO, is on the deployment of an outdated ERP system purchased five years ago. John’s company is a process-based manufacturer and Anne’s ERP solution is a better fit for configure to order which leads to limitations. However, improving order-to-cash is cycles for both timing and accuracy is important to the Chief Financial Officer, so Anne is getting funding and attention. Anne is a lean disciple and sees all inventory as Muda. She lacks the appreciation for the need for inventory as a buffer. In addition, Anne wants to deploy the ERP solution to improve inventory targets but does not realize that an ERP solution is primarily focused on improving safety stock (versus form and function of inventory). The specific solution has little capability to improve cycle stock management through better production planning, or in transit inventory based on transportation decisions.

John’s Advanced Planning Solution provider wants to sell him more software and has little empathy for the failed implementation. While John feels that the reimplementation of the best-of-breed solution could improve results, he is not able to get funding.

So, how does John maneuver through the ring of fire? Here is my suggestion:

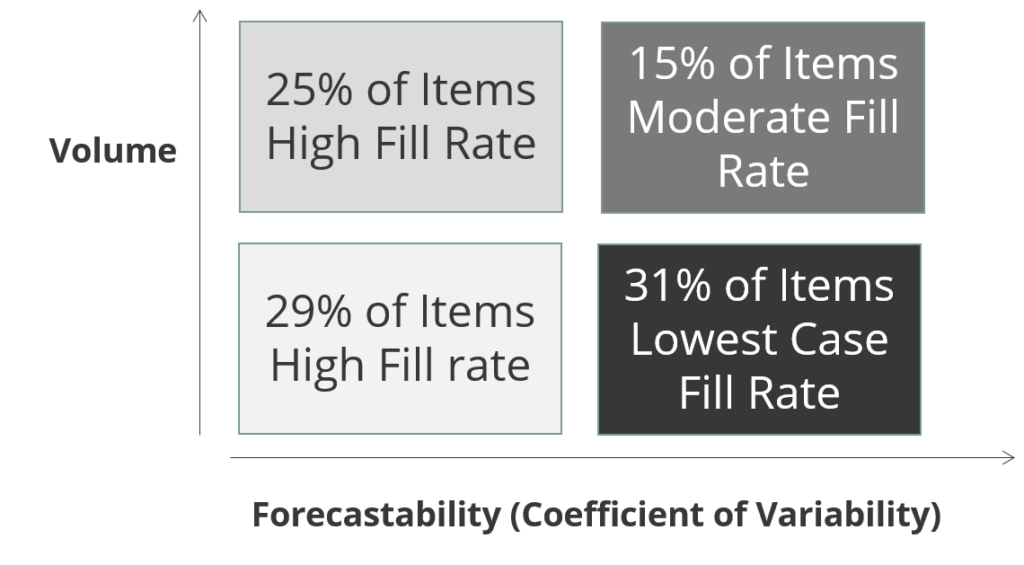

Try to Align the Organization on the Definition of Supply Chain Excellence. The way to drive alignment is through data. Through data analysis help the team understand the trade-off (the effective frontier) and the need for a clear definition of supply chain excellence. To accomplish this goal, analyze forecastability (analysis of Coefficient of Variation (COV)), Forecast Value Added analysis (FVA), fill rate, and product flows. Graph the flows over time in these four quadrants:

My belief is that John will find that less than 50% of the product line can be effectively handled based on the CFO’s definition of efficiency. (The definition of the efficient supply chain in this model is the lowest cost per unit. This definition is only effective when applied to high volume and predictable items.) My belief is that John’s product line is growing less predictable (growing item complexity) and that the FVA is degrading. I advised John to type the product flows and graph the shifts to help the executives to visualize the flows and the limits of the efficient supply chain definition. For example, typically growth items–new product launch and special products–cannot be managed as an efficient supply chain. Instead, the techniques need to focus on agility (the design of the supply chain for reliable cost, quality and customer service) given the level of variability.

Make Anne Successful. I advised John to use the improved data from ERP to improve planning and give Anne the credit. By making Anne successful, he will gain an ally. He should look for all of the wins from ERP while helping Anne to see the limitations of ERP in driving supply chain excellence.

Share Data on Inventory: I also asked John to analyze the form/function and health of the inventory. The Company is currently performing below peer group with an opportunity to improve inventory turns by 15%. For example, if safety stock is only 30% of the inventory and this is the focus of the ERP deployment, the answer is not ERP. I advised John to ask for help to improve inventory health. His options are to reduce obsolesce and cycle stock management through production planning, and to design the supply chain to balance the form/function of inventory.

Analyze Root Cause for Order Reliability. Peter, the COO, wants to improve order reliability. However, order fulfillment is not measured, and he is stonewalling the implementation of warehouse management. He does not see the value for the cost of warehouse management. (He does not understand the value of a better perpetual inventory signal and the tie to improved order fulfillment when it comes to warehouse management.)

I asked John to plot the root cause analysis of order shorts and late deliveries. In the summary, I asked him to analyze when the organization knew the item would be short and what they did about it. Helping Peter understand process and data latency on order reliability is the opportunity.

Moving Through The Ring Of Fire

The opportunity for John is to influence the executive group to align. This best happens through storytelling and data analysis to support an opportunity in the business that is shared by all (like customer order reliability).

Large organizations are very political and require strong influence skills and building a guiding coalition. Don’t fight the fire, use data to drive alignment. Good luck if you like John, find yourself in the middle.

Would Love Your Help

I am researching the value of a network in managing contract manufacturing and could use your help. If you fill out one of my surveys on LinkedIn, I keep the information on the respondent–name, company, title, and individual comments–confidential. I only share the results in aggregate. Have a great weekend.