Megatrends Shaping Supply Chain Innovation

The Logistics & Supply Chain Management Society

MAY 28, 2022

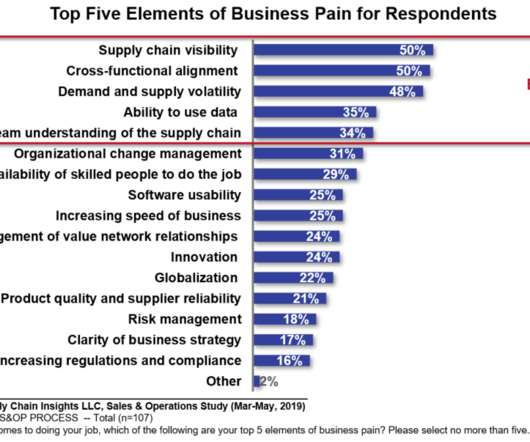

Megatrends Shaping Supply Chain Innovation. And what are the key industry trends and innovations? In E2open’s Supply Chain Innovation Report 2021 , 73% of respondents claimed their supply chain is either moderately, slightly, or not at all resilient. Supply chain mapping is key to ongoing innovation.

Let's personalize your content