The Internet of Things in the Supply Chain

Enterra Insights

JULY 25, 2022

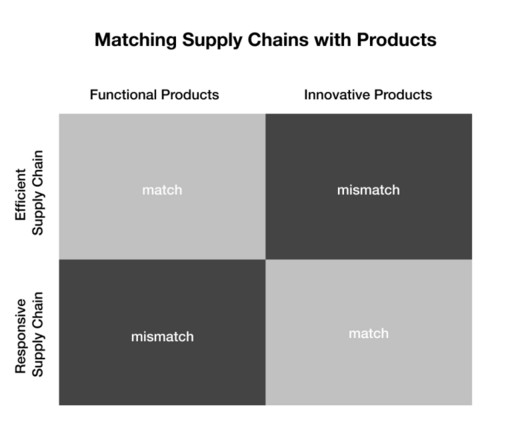

Retailers expect to be connected to manufacturers. Manufacturers expect to be connected to suppliers. ”[1] He adds, “Using sensors enabled by the internet of things (IoT), [stakeholders] can keep tabs on shipment whereabouts and conditions, enabling proactive communications to customers about the status of their orders.”

Let's personalize your content