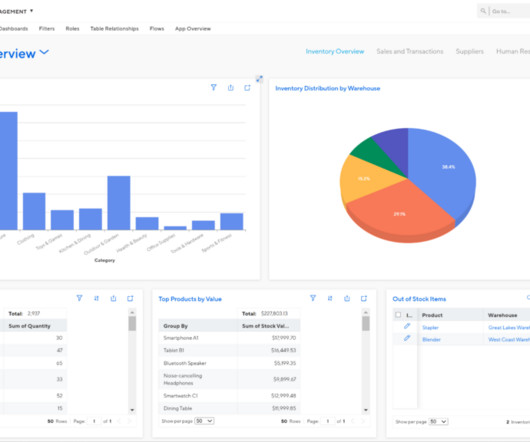

Inventory Management vs. Warehouse Management

The Logistics of Logistics

FEBRUARY 11, 2022

Inventory Management vs. Warehouse Management. Original article: Inventory Management vs. Warehouse Management. That may be because a company might already have an inventory system and wonders what additional capabilities they will get with a new WMS.

Let's personalize your content