Inventory Management in a High Inflation Environment

Logistics Viewpoints

FEBRUARY 2, 2022

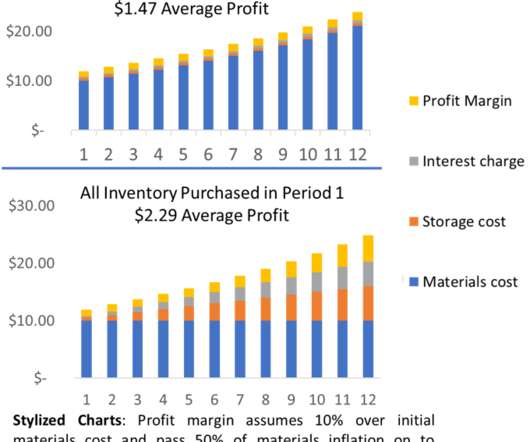

Inflation’s effects on inventory management policies are likely far from top of the mind of Logistics Viewpoints readers in today’s challenging times. However, today’s elevated rate of inflation warrants a closer look at optimal inventory policies. Inventory Costs and Risks.

Let's personalize your content