Introducing :o9 Solutions’ SCM software for the first time in Japan

o9 Solutions

OCTOBER 30, 2020

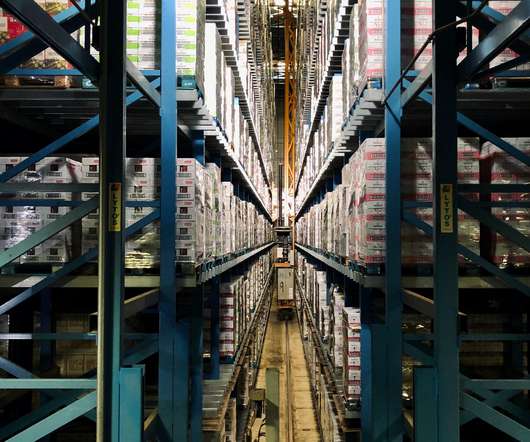

Strengthening Digital SCM Services for Retail and Distribution Industries in Japan. Marubeni Corporation (hereinafter, “Marubeni”), :o9 Solutions Japan K.K. The post Introducing :o9 Solutions’ SCM software for the first time in Japan appeared first on o9 Solutions. About Nomura Research Institute, Ltd.

Let's personalize your content