What is Lean Retail (+ Why Retailers Must Embrace It)

ToolsGroup

DECEMBER 16, 2021

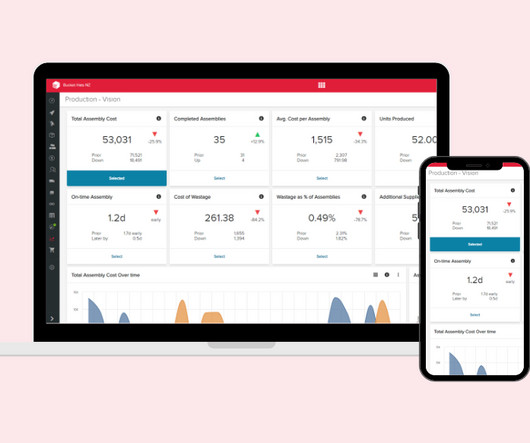

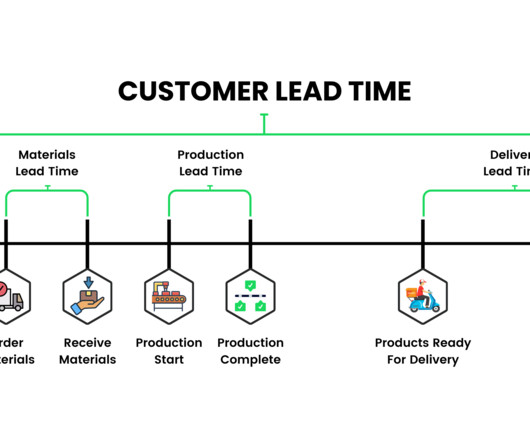

Whereas retailers once purchased merchandise largely based on the gut instinct of trend-savvy buyers and the push of whatever manufacturers tried to sell them, nowadays, they need to take a much more customer-focused and data-centered approach. What is Lean Retail? The impact of lean retail on supply chain management.

Let's personalize your content