Are you interested in understanding how businesses effectively manage their supply chains? Look no further – this guide is here to help you grasp the fundamentals of supply chain management (SCM) and how it can lead to success. Whether you’re a business owner, manager, or simply curious about the inner workings of the global economy, this article will provide you with a solid foundation.

In this comprehensive guide, we’ll explore the key components of supply chain management, best practices, and how they can be tailored to specific industries. We’ll also delve into the importance of technology and data analytics in optimizing supply chain operations.

So, if you’re ready to enhance your understanding of supply chain management and unleash its potential for success, let’s dive in!

Sign Up for SCMDOJO Pro Membership

Importance of Effective Supply Chain Management

Supply chain management is not just about moving products from point A to point B – it’s a strategic approach that encompasses the entire network of processes involved in delivering goods and services to customers. From sourcing raw materials, manufacturing, and storage, to transportation and distribution, SCM ensures efficiency and cost-effectiveness throughout the entire journey.

Effective supply chain management is crucial for businesses to gain a competitive edge in today’s global marketplace. By streamlining processes, reducing costs, and improving customer satisfaction, companies can achieve higher profitability and sustainability. A well-managed supply chain enables businesses to respond swiftly to market demands, mitigate risks, and seize growth opportunities.

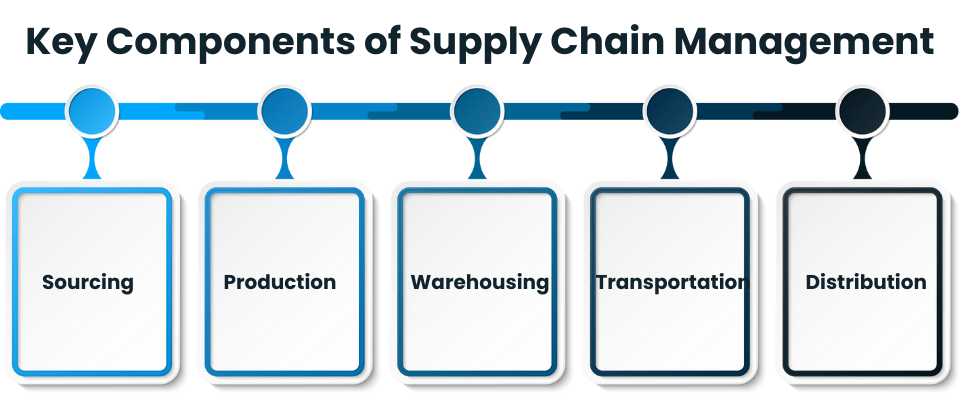

Key Components of Supply Chain Management

To understand supply chain management better, let’s dive into its key components. The supply chain consists of several interconnected stages, each playing a vital role in the overall process.

Planning:

This stage involves forecasting demand, setting production schedules, and creating a strategic framework for the entire supply chain. Planning ensures that resources are allocated effectively and that production and distribution meet customer demand.

Sourcing:

Sourcing is all about finding reliable suppliers, negotiating contracts, and managing relationships. It encompasses activities such as procurement, supplier selection, and evaluation. A well-established sourcing strategy helps businesses secure the best quality materials at the most competitive prices.

Production:

This stage involves transforming raw materials into finished products. Efficient production processes, quality control measures, and lean manufacturing techniques are crucial for optimizing productivity and minimizing waste.

Warehousing:

Warehousing involves the storage and management of inventory. Effective warehousing strategies ensure that goods are properly stored, organized, and readily available for distribution when needed. It also involves inventory management, order fulfillment, and monitoring stock levels.

Transportation:

Transportation plays a pivotal role in supply chain management. It involves the movement of goods from one location to another, whether by road, rail, air, or sea. Efficient transportation systems minimize delays, reduce costs, and ensure timely delivery to customers.

Distribution:

Distribution involves the final stage of getting products into the hands of customers. It includes activities such as order processing, packaging, and delivery. A well-designed distribution network ensures that products reach customers in the fastest and most cost-effective way possible.

By effectively managing these key components, businesses can achieve a streamlined and efficient supply chain, resulting in improved customer satisfaction and increased profitability.

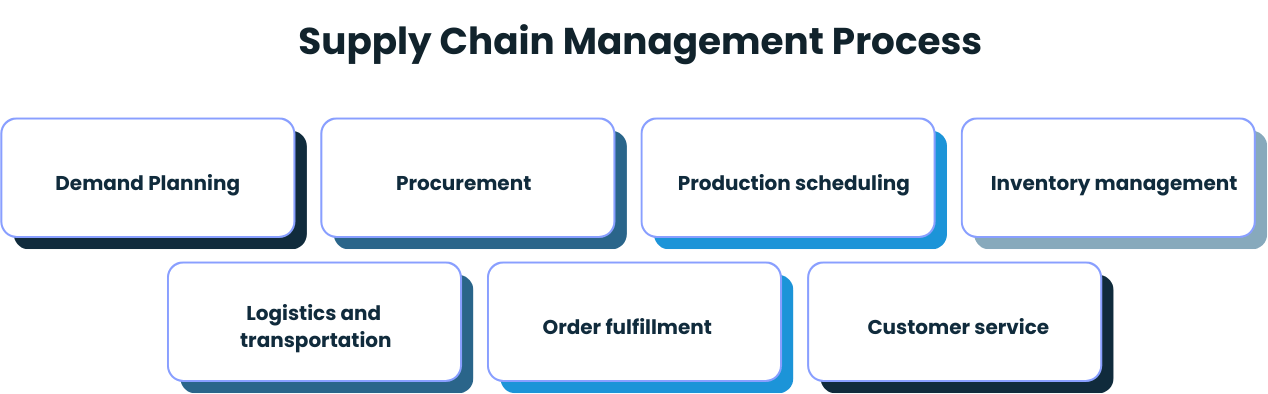

Supply Chain Management Process

Now that we have an understanding of the key components, let’s explore the supply chain management process in more detail. The supply chain management process consists of several interconnected steps that collectively ensure the smooth flow of goods and services.

Demand Planning:

Demand planning involves forecasting customer demand based on historical data, market trends, and other relevant factors. Accurate demand forecasting enables businesses to optimize production levels, reduce inventory costs, and meet customer expectations.

Procurement:

Procurement is the process of sourcing and acquiring the necessary raw materials, components, or finished goods from suppliers. This involves supplier selection, negotiation, and contract management to ensure timely and cost-effective procurement.

Production Scheduling:

Production scheduling determines the optimal sequence and timing of production activities to meet customer demand while minimizing costs and maximizing efficiency. It involves coordinating production processes, managing resources, and aligning production levels with demand forecasts.

Inventory Management:

Inventory management is crucial for maintaining optimal inventory levels. It involves tracking stock levels, monitoring demand fluctuations, and implementing efficient inventory control measures to prevent stockouts or excess inventory.

Logistics and Transportation:

Logistics and transportation play a crucial role in ensuring the smooth flow of goods from suppliers to customers. This includes selecting the most efficient transportation routes, managing carrier relationships, and optimizing transportation costs.

Order Fulfillment:

Order fulfillment involves processing customer orders, picking and packing products, and arranging for their delivery. Efficient order fulfillment processes ensure timely and accurate delivery, enhancing customer satisfaction.

Customer Service:

Customer service is an integral part of supply chain management. It involves addressing customer inquiries, managing returns and exchanges, and maintaining strong customer relationships. Excellent customer service contributes to customer loyalty and brand reputation.

By following these steps in the supply chain management process, businesses can optimize their operations, reduce costs, and enhance customer satisfaction, ultimately leading to business success.

Common Challenges in Supply Chain Management

While effective supply chain management can yield significant benefits, it also comes with its fair share of challenges. Let’s explore some of the common challenges faced by businesses in managing their supply chains.

Demand Uncertainty:

Fluctuating customer demand can make it challenging to accurately forecast demand and plan production levels. Unexpected spikes or dips in demand can lead to inventory imbalances, stockouts, or excess inventory.

Supplier Management:

Managing relationships with suppliers can be complex, especially when dealing with multiple suppliers across different locations. Communication and coordination issues, quality control problems, and supplier reliability can impact the overall supply chain.

Inventory Optimization:

Balancing inventory levels to meet customer demand while minimizing costs is a constant challenge. Too much inventory ties up capital and increases storage costs, while too little inventory can result in stockouts and lost sales.

Transportation and Logistics:

Managing transportation logistics, especially in global supply chains, can be complex and costly. Factors such as transportation delays, capacity constraints, and rising fuel prices can impact delivery times and increase costs.

Information Visibility:

Lack of real-time information and visibility across the supply chain can lead to inefficiencies and delays. Timely and accurate data is crucial for making informed decisions, managing inventory, and responding to customer demands.

By addressing these challenges through effective strategies, businesses can overcome obstacles and optimize their supply chain operations for success.

Strategies for Optimizing Supply Chain Management

To overcome the challenges in supply chain management and achieve optimization, businesses can adopt various strategies. Let’s explore some key strategies for optimizing supply chain management.

Collaboration and Partnerships:

Collaborating with suppliers, customers, and other stakeholders can lead to shared knowledge, reduced costs, and improved efficiency. Building strong relationships and partnerships fosters collaboration and enables better coordination across the supply chain.

Lean Principles:

Implementing lean principles helps eliminate waste, improve efficiency, and reduce costs. Techniques such as just-in-time manufacturing, continuous improvement, and value stream mapping can streamline processes and increase productivity.

Technological Integration:

Embracing technology and integrating it into supply chain processes can enhance visibility, automate tasks, and improve decision-making. Technologies such as enterprise resource planning (ERP) systems, warehouse management systems (WMS), and transportation management systems (TMS) can streamline operations and improve efficiency.

Risk Management:

Proactively identifying and managing risks is crucial for supply chain success. Developing contingency plans, diversifying suppliers, and implementing robust risk mitigation strategies help businesses navigate unforeseen events and disruptions.

Continuous Improvement:

Regularly reviewing and improving supply chain processes is essential for optimization. Analyzing key performance indicators (KPIs), conducting regular audits, and seeking feedback from customers and stakeholders can identify areas for improvement and drive continuous improvement initiatives.

By adopting these strategies, businesses can optimize their supply chain management practices and achieve greater efficiency, cost-effectiveness, and customer satisfaction.

Technologies and Tools for Supply Chain Management

Technological advancements have revolutionized supply chain management, providing businesses with powerful tools to enhance efficiency and optimize operations. Let’s explore some key technologies and tools that can help businesses streamline their supply chain management processes.

Enterprise Resource Planning (ERP) Systems:

ERP systems integrate various business functions, such as finance, inventory management, and production planning, into a centralized platform. This enables real-time visibility, data sharing, and streamlined processes across the entire supply chain.

Warehouse Management Systems (WMS):

WMS software automates and optimizes warehouse operations, including inventory management, order fulfillment, and tracking. It provides real-time visibility into inventory levels, improves picking and packing accuracy, and enhances overall warehouse efficiency.

Transportation Management Systems (TMS):

TMS software helps manage transportation logistics by optimizing route planning, carrier selection, and load optimization. It enables businesses to reduce transportation costs, improve delivery times, and enhance overall supply chain visibility.

Demand Planning and Forecasting tools:

Demand planning and forecasting tools leverage historical data, market trends, and statistical algorithms to forecast customer demand accurately. These tools help businesses optimize production levels, reduce inventory costs, and improve customer satisfaction.

Supply Chain Analytics:

Supply chain analytics tools utilize data analytics and machine learning algorithms to gain insights into supply chain performance, identify bottlenecks, and optimize operations. These tools enable businesses to make data-driven decisions and continuously improve supply chain processes.

By leveraging these technologies and tools, businesses can enhance visibility, automate processes, and make informed decisions, ultimately optimizing their supply chain management practices.

Key Performance Indicators (KPIs) in Supply Chain Management

To measure the effectiveness of supply chain management practices, businesses rely on key performance indicators (KPIs). KPIs provide quantifiable metrics that reflect the performance and efficiency of various supply chain processes. Let’s explore some common KPIs in supply chain management.

Order cycle time:

Order cycle time measures the time taken from when an order is placed to when it is delivered to the customer. It reflects the speed and efficiency of order processing, picking, packing, and delivery.

Inventory turnover:

Inventory turnover measures how quickly a company sells its inventory and replaces it with new stock. It indicates the efficiency of inventory management and helps identify excess or slow-moving inventory.

Perfect order rate:

The perfect order rate measures the percentage of orders that are delivered to customers without any errors, delays, or issues. It reflects the overall accuracy and reliability of order fulfillment processes.

On-time delivery:

On-time delivery measures the percentage of orders that are delivered to customers within the promised delivery timeframe. It reflects the efficiency of transportation and logistics operations.

Supplier performance:

Supplier performance measures the reliability and performance of suppliers based on metrics such as on-time delivery, quality of products, and adherence to contractual terms. It helps evaluate and manage supplier relationships effectively.

Supply chain cost:

Supply chain cost measures the total cost involved in managing the supply chain, including procurement, production, transportation, warehousing, and distribution costs. It helps identify areas for cost reduction and optimization.

By monitoring and analyzing these KPIs, businesses can identify areas for improvement, track progress, and make data-driven decisions to optimize their supply chain management practices.

Examples of Successful Supply Chain Management Practices

Let’s explore some real-world examples of successful supply chain management practices to gain insights into how businesses have achieved supply chain excellence.

Amazon:

Walmart:

Zara:

Procter & Gamble:

These examples highlight the importance of strategic planning, collaboration, advanced technology adoption, and continuous improvement in achieving supply chain excellence.

Conclusion: The Future of Supply Chain Management

As the business landscape continues to evolve, supply chain management will play an increasingly critical role in achieving success. The future of supply chain management will be shaped by technological advancements, data-driven decision-making, and a focus on sustainability and resilience.

Businesses that embrace digital transformation, leverage advanced technologies, and adopt agile supply chain strategies will gain a competitive edge in the global marketplace. The ability to anticipate and respond quickly to changing customer demands, mitigate risks, and optimize operations will be crucial for success.

By understanding the key components, challenges, strategies, and technologies in supply chain management, businesses can unlock the potential for success and create efficient, cost-effective, and customer-centric supply chains.

So, whether you’re a business owner, manager, or someone interested in the complexities of supply chain management, this guide equips you with the knowledge and insights to navigate the dynamic world of supply chains and achieve success in the global economy.