This Week in Logistics News (January 6 – 12)

Logistics Viewpoints

JANUARY 12, 2024

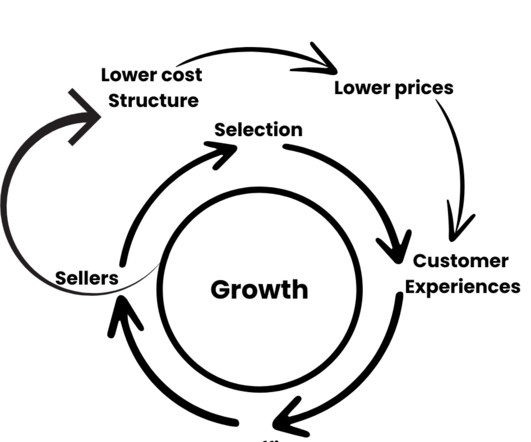

And now on to this week’s logistics news. In 2023, Amazon experimented with new logistics strategies and technologies to quickly fulfill and deliver orders, and these changes paid off big. The faster delivery times this year specifically may be attributed to changes in Amazon’s logistics strategy. That’s all for this week.

Let's personalize your content