Los Angeles and Long Beach Terminal Congestions

CH Robinson Transportfolio

OCTOBER 29, 2014

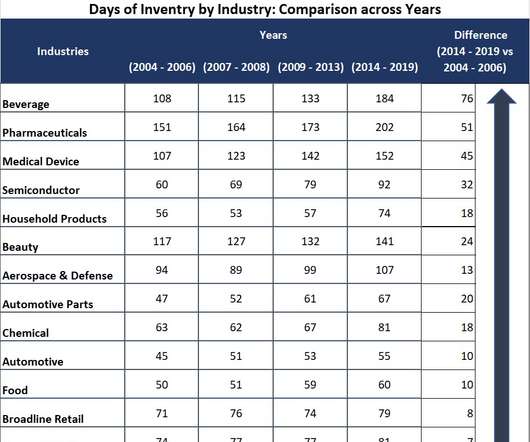

Due to a possible strike over the USWC, most retailers took precautions and have been moving a high level of inventory replenishment in preparation for a robust year-end shopping season. The post Los Angeles and Long Beach Terminal Congestions appeared first on Transportfolio. Global Transportation Supply Chain'

Let's personalize your content