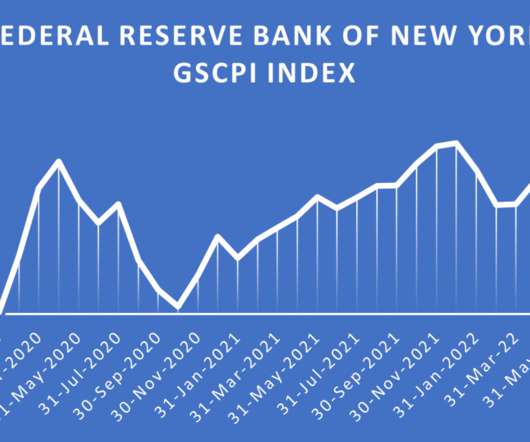

Inventory and Inflation

Enterra Insights

JUNE 22, 2022

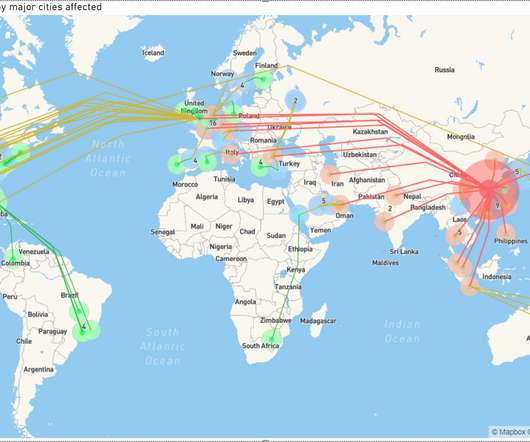

The irony of excess inventory. In the grocery sector, for example, correspondents from the New York Times observe, “[Grocery shoppers] doing their weekly runs to grocery stores [are finding] some items that used to be plentiful have been missing for months.”[2] Excess inventory was also caused by the Bullwhip Effect.

Let's personalize your content