What is Lean Retail (+ Why Retailers Must Embrace It)

ToolsGroup

DECEMBER 16, 2021

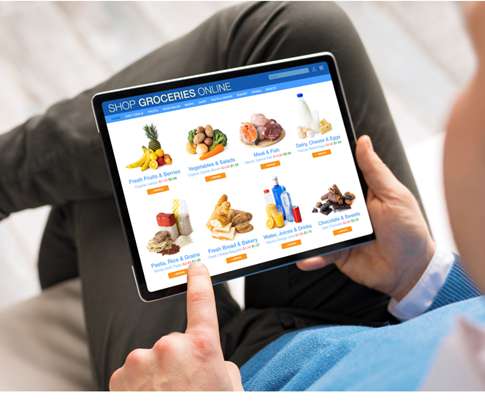

With the advent of globalization, the Internet, and more recently, the proliferation of mobile technology into every aspect of our lives, there has been a remarkable shift in the world of retail from a product-centric to customer-centric model. What is Lean Retail? The impact of lean retail on supply chain management.

Let's personalize your content