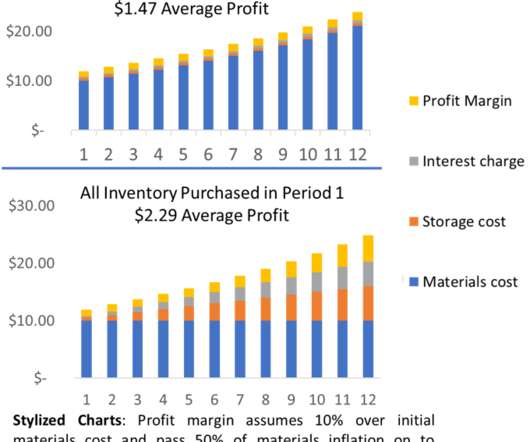

Head to Head: Which Service Parts Inventory Policy is Best?

The Smart Software

FEBRUARY 20, 2024

Our customers have usually settled into one way to manage their service parts inventory. The professor in me would like to think that the chosen inventory policy was a reasoned choice among considered alternatives, but more likely it just sort of happened. The post Head to Head: Which Service Parts Inventory Policy is Best?

Let's personalize your content