The Give and Take of Multi-Carrier Parcel Shipping Technology

Logistics Viewpoints

MARCH 24, 2022

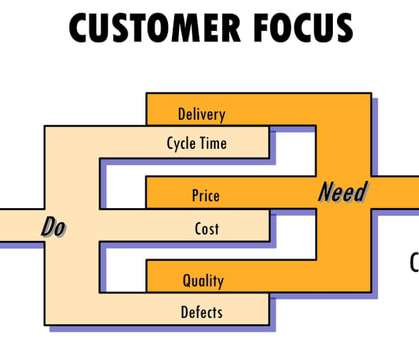

Retailers also took steps to contain costs and preserve margins as they reoriented toward e-commerce like never before, including putting solutions in place to more effectively navigate carrier capacity caps and improve the visibility, accessibility, and mobility of inventory. Meet the basic needs.

Let's personalize your content