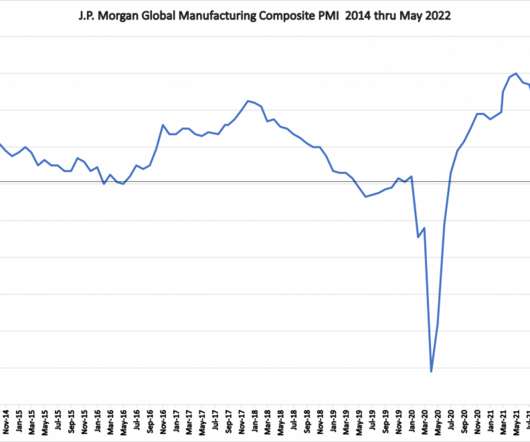

Relatively Cautious Global Production and Supply Chain Indices for February 2022

Supply Chain Matters

MARCH 3, 2022

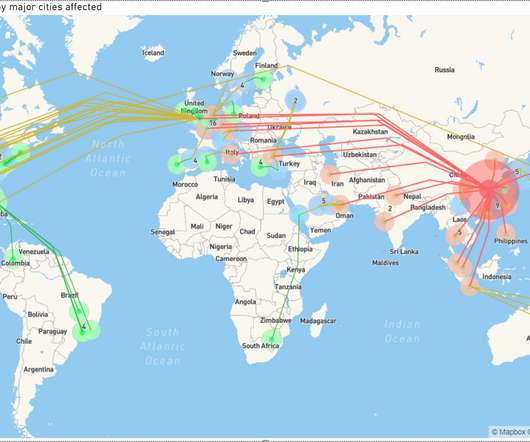

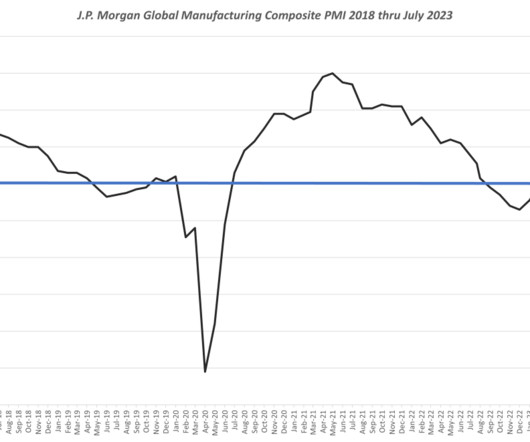

Global wide production, transportation and logistics activity levels reported for February, but continued rather concerning data related to global transportation service levels and cost. The IHS Markit Vietnam Manufacturing PMI® rose again to a level of 54.3 Global and Domestic Transportation and Logistics Indices.

Let's personalize your content