Supply Chain Risk Management : The Challenges Driving Increased Interest in Managed Service

GlobalTranz

AUGUST 4, 2021

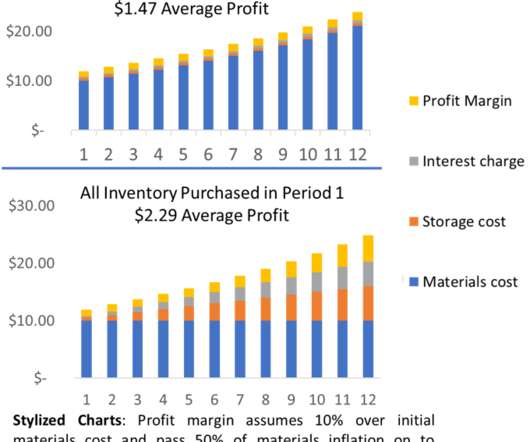

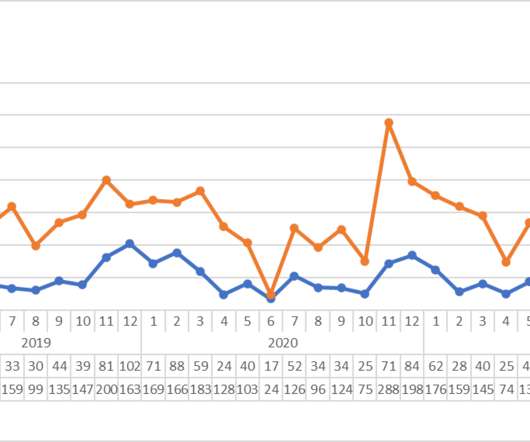

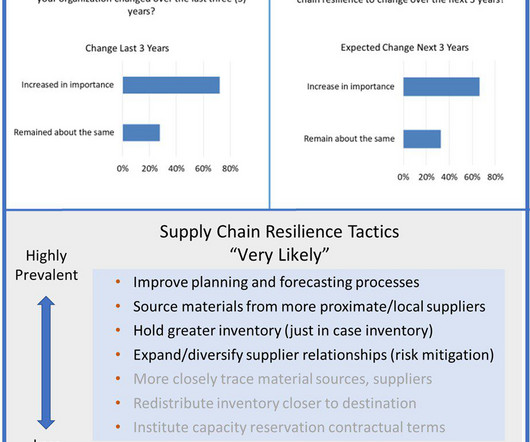

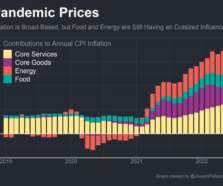

Any discussion on supply chain risk management and applying managed transportation to help prevent risks from coming to fruition is incomplete without touching on the pandemic to overcome supply chain disruption. Market Volatility Continues to Undermine Supply Chain Risk Management.

Let's personalize your content