How to Navigate ESG Risk with Supplier Management Software

QAD

MAY 23, 2023

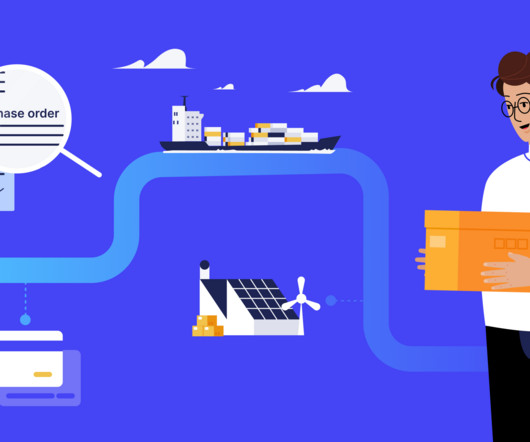

Get Ahead of ESG Concerns with Supplier Management Software Most businesses can’t expect to dictate suppliers’ material sourcing decisions, but they can choose to work with ethical suppliers who understand and support ESG compliance.

Let's personalize your content