8 Examples of Kanban in Lean Manufacturing

Unleashed

MARCH 2, 2022

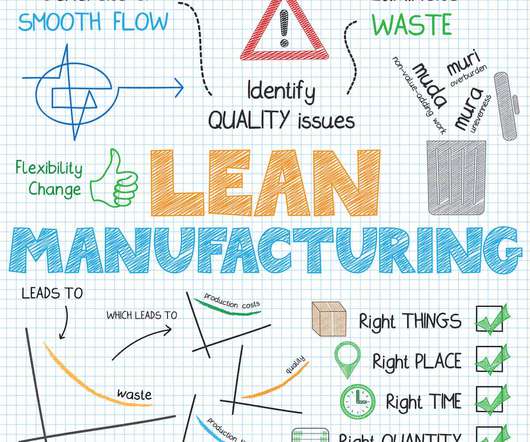

Here we give you eight real-world examples of how businesses use Kanban, a popular lean tool that’s helped companies in a huge range of sectors improve efficiency – especially those in the manufacturing industry. Kanban came from the same place as the wider principles of lean manufacturing: Toyota.

Let's personalize your content