ZF’s Transition from Lean to Supply Chain Resilience

Logistics Viewpoints

OCTOBER 31, 2022

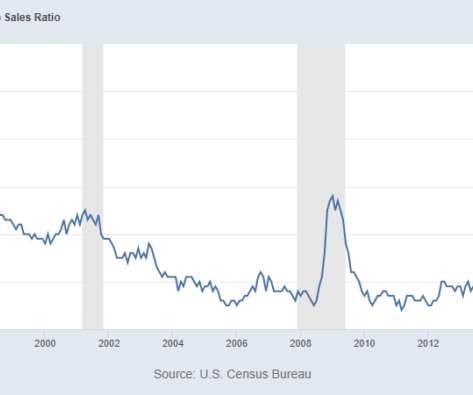

I interviewed John Sobeck, Vice President Material Management Services and Supply Chain 4.0 at the ZF Group, about their digital supply chain transformation journey. The ZF supply chain is complex. ZF’s Digital Supply Chain. The Transition from Lean to Resilience. at the ZF Group.

Let's personalize your content