From Predictions to Operations: Compelling Supply Chain AI Use Cases

A report by McKinsey shows that early adopters of AI in the supply chain have improved their inventory levels by 35%, reduced logistics costs by 15%, and enhanced service levels by 65%, vis-a-vis competitors who were slow to embrace AI.

Clearly, Artificial Intelligence (AI) is unlocking so much potential for growth and efficiency in logistics and supply chain management.

Even as some supply chains are facing challenges of implementing AI for multiple reasons, some others are already setting great examples. We’ve seen the top use cases for AI emerge from our own work at ThroughPut and here are a number of them.

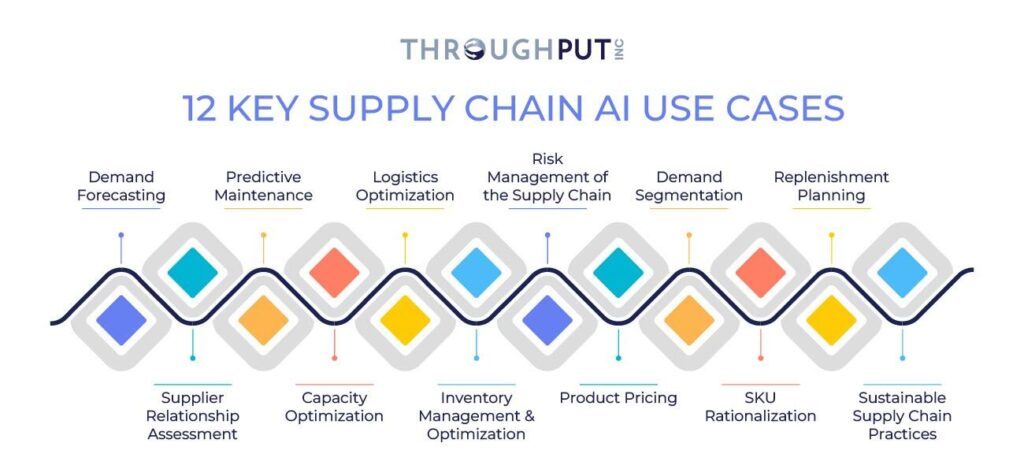

12 Key Supply Chain AI Use Cases

Supply chain AI Use Case 1: Demand Forecasting

Market instability is the Achilles heel of demand forecasting right now. With rapid fluctuations and uncertainty, predicting customer demand is like shooting in the dark. Your target keeps changing and as a result, you are missing the mark more than you’d ever want to.

And the effect of inaccurate demand forecasting is felt across the supply chain. Inventory pile-ups. Unsold products on store shelves. Confusion around pricing and promotion. Operational chaos and so much more. Just about everyone in the supply chain gets negatively impacted by wrong forecasts.

And you’re not to blame. With so many changing variables, excel sheets or human intervention alone can’t gain the level of visibility needed to forecast the future. Now that’s where the first use case of AI in the supply chain emerges: AI for demand forecasting.

Leveraging AI for demand forecasting means:

- You can analyze any amount of historical data and current trends from external sources to predict future demands more accurately.

- You can identify near-term market shifts with greater precision.

- You can reduce risks of lost opportunities or sales resulting from inventory shortages and low stock levels.

- You can comprehend market dynamics and shifting customer preferences in real-time.

In short, AI for demand forecasting facilitates the creation of an agile ecosystem where companies can predict demand in real-time and can quickly adapt to meet the changing demands of their customers.

We call this AI-powered ability to predict near-term demand as demand sensing.

Supply Chain AI Use Case 2: Supplier Relationship Assessment (SRM)

Dependency on underperforming or under-delivering suppliers isn’t just a minor inconvenience; it’s a critical vulnerability that could bring your operations to a standstill—a costly misstep you’d undoubtedly prefer to sidestep.

Yet, the challenge doesn’t lie merely in recognizing this risk but in the complex process of assessing and nurturing supplier relationships. Traditional manual approaches and one-size-fits-all tech solutions fall short, offering scant assistance. The solution? AI for supplier relationship assessment.

Embracing AI for supplier management within the supply chain translates to:

- Optimizing your sourcing decisions through critical data insights. AI algorithms evaluate supplier performances and analyze compliance with risk factors that help you manage supplier relationships effectively.

- You can conveniently work with the right suppliers by analyzing pricing, quality, and delivery times as the system helps you identify reliable suppliers, thereby, streamlining the procurement processes.

- Your sourcing department can save valuable time because AI tools analyze suppliers with the aid of relevant data points and metrics and match them with the contract opportunities available.

Supply Chain AI Use Case 3: Predictive Maintenance

Unexpected equipment failures and downtime is not new to you. It directly impacts your workflow and productivity. Plus, other significant losses are production time, resources, and of course, money.

Premature replacement costs may not be part of your budget. To top it off, the urgency of the situation can increase the chances of compromising safety standards and employee welfare. Understandably, it puts you in a vulnerable spot. Predictive maintenance through AI is supply chain AI use case number three.

Leveraging AI in the supply chain for predictive maintenance means:

- AI can predict likely failures of parts and components proactively. This, in turn, can help schedule maintenance much before the machine breaks down in real-time, thereby, reducing downtime and high maintenance costs.

- You can focus and budget for timely maintenance since AI algorithms can interpret sensor-generated data more accurately to indicate friction, stress, wear and tear, misalignment, etc. before they occur, helping avoid sudden breakdowns.

- Most of all, predictive maintenance strengthens each link in the network. Truck drivers can proactively maintain their vehicles. Factories can have a dynamic approach to replacing aging machinery and parts, conveyor belts, etc. for smooth product movement across the line. Warehouse staff can stay on top of their replenishment orders to minimize gaps in the supply chain.

Supply Chain AI Use Case 4: Capacity Optimization

The market out there is cutthroat and competitive and this is no secret. You need to balance between meeting demands optimally and adopting cost-effective production means.

Failure to invest in capacity management can affect your ability to predict and meet demand and manage resources optimally. Consequently, either your business is overproducing or underutilizing the operation capacities. Net result: the operational costs are ever-increasing, you are missing deadlines, and product quality seems to be getting compromised. All the while customers seem to be flocking to your closest competitor. Hitting rock bottom in terms of profitability is the worst that can happen but with AI you can turn the tables, and that too, fast.

Leveraging AI in the supply chain for capacity planning means:

- You can forecast demand accurately with real-time data analysis, helping you optimize resources and capacity.

- You can make informed and agile decisions and strategize proactively to meet the demands of the changing market conditions.

- You can reduce idle time, avoid wastage, and minimize unrequired investments.

- You can reduce costs that are tied to idle or excess inventory, empowering your organization to meet customer requirements with minimal lead times.

Supply Chain AI Use Case 5: Logistics Optimization

Delivery delays are one of the biggest struggles right now in the supply chain. It not only hampers your brand image but also impacts customer loyalty. Moreover, inefficiencies in the logistics operations have resulted in increasing carbon footprint on the planet.

Logistics network inefficiencies can also leave costly trails. As transportation costs soar and assets remain underutilized, businesses may find themselves struggling to maintain operations, let alone drive growth. This is particularly true in the face of fluctuating demands and ever-changing market conditions.

To navigate these challenges, embracing AI in logistics optimization can be ideal.

Leveraging AI in the supply chain for logistics optimization can:

- Help you deliver the right product at the right time to the right client. All of this at the best price. With the real-time monitoring and tracking of shipments, AI tools ensure that goods are delivered on time and optimally.

- Optimize delivery routes, improve freight operations, and propose the best shipping methods to you. The overall emphasis of AI helps make the supply chain more responsive and efficient.

- Help you optimize logistics in a way that there are negligible supply chain interruptions that future-proof the company from unforeseen issues.

Supply Chain AI Use Case 6: Inventory Management & Optimization

A common issue that disrupts the supply chain is when there is a disconnect between demand and supply.

You could be overstocking, consuming valuable space, and tying up capital that could have been invested elsewhere. Or, you could have understocked, lost out on sales, and risked stockouts, leading to dissatisfied customers.

Inventory is the thread here that connects supply and demand. When the inventory is not managed up to the mark, your business could start to spiral downwards in no time.

That’s because the ability of your business to respond to market trends and fluctuations is minimally low. All of this impacts profitability but more importantly, affects your company image.

Leveraging AI in the supply chain for inventory management can:

- Help you manage the flow of goods from the shop floor to the end user seamlessly. This involves multiple processes starting from procuring raw materials, to overseeing inventory levels, storing, replenishing, distribution, and more. The replenishment process is a core area of inventory management and optimization. AI tools can consider different factors like demand patterns, lead time, storage capacity, etc., to adjust the reorder quantities and points dynamically and automatically generate accurate replenishment orders. Inventory optimization with AI helps avoid missed sales opportunities due to ‘out-of-stock’ or ‘low stock’ conditions.

- Assist you in identifying patterns and fluctuations facilitating the business to optimize its inventory levels in real-time. AI-based algorithms work with historical and large volumes of data to analyze current market and social trends, and various external factors for generating precise demand forecasts.

- Help you manage thousands of SKUs since AI tools can easily help classify and categorize products based on different parameters like seasonality, demand patterns, profitability, etc. Thus, you can prioritize fast-moving or high-value products. Along with inventory optimization, the tools help in effective resource allocation too.

Supply Chain AI Use Case 7: Risk Management of the Supply Chain

Risk is an inevitable part of the business world.

Therefore, all businesses integrate risk management as an essential part of their operations. In the supply chain, not addressing risks can be disastrous as your business could be vulnerable to various underlying risks that can have catastrophic financial losses. It could be a deterrent to your brand image too.

Unfortunately, supply chains have multiple players and these can impact the movement across the chain, from raw materials to end products. Geopolitical tensions, for example, are an existing issue in the supply chain today. Natural disasters, supplier failures, pandemics, etc. can halt your operations considerably.

Proactiveness is the need of the hour. You have to be on your front foot to mitigate risks.

What can help? AI for sure.

Leveraging AI in the supply chain for risk management means:

- You can predict potential risks with AI’s powerful data analytics in real-time.

- Your shipments get re-routed with AI’s predictions of weather conditions and disruptions in transportation routes based on patterns. This helps prevent delays.

- You can effectively forecast future risks and identify patterns with predictive analytics.

- You get enhanced visibility into the supply chain thus facilitating corrective actions impromptu.

- You can pick reliable suppliers based on historical performance, financial stability, geopolitical events, etc. with the help of AI. This can make a lot of difference in anticipating and mitigating risks.

- Your contingent plans are ready, your business continuity is maintained and you enjoy a competitive edge.

Supply Chain AI Use Case 8: Product Pricing

Manual and even automated pricing methods can be static and detrimental to the growth of your business. You will fail to capitalize on opportunities to maximize profits during peak demand seasons. Similarly, clearing excess inventory during slower demand periods can be challenging.

If you do not practice dynamic product pricing in the supply chain, your inflexibility can limit your ability to respond swiftly to market changes, demand fluctuations, and competitive pressures. Needless to say, you lose out on earning more revenues, struggling to adjust to cost variations in the chain.

Leveraging AI in the supply chain means

- That you can avoid overages and stockouts and create opportunities to increase revenues. In AI tools, deep-learning algorithms adjust prices automatically per changing demands, trends, and market conditions.

- You can monitor competitor prices in real-time and keep a watch on the demand-supply metrics, enabling informed decisions.

- Your business operates on the front foot and is better equipped to respond to rapidly changing market conditions. Overhead costs can be reduced and sales volumes can be increased.

Supply Chain AI Use Case 9: Demand Segmentation

If you are treating the market and your customers as a homogeneous whole, you are not recognizing and capitalizing on the varying needs and behaviors of different customer segments. You are missing opportunities leading to significant inefficiencies. That’s a big oversight resulting in suboptimal inventory levels, inappropriate product mix, and ineffective marketing strategies. You are risking too much by taking chances with customer satisfaction and loyalty. Demand segmentation can make you capable of responding to market dynamics but neglecting it can affect your sales and margins, especially in the more lucrative segments.

Leveraging AI in the supply chain for demand segmentation means:

- You can discover hidden customer segments through the intricate patterns and correlating complex datasets of AI algorithms.

- You can produce and distribute customized products, packaging, and configurations meeting the specific needs of different segments with greater accuracy with AI.

- You can get into granular segmentation based on varying behavioral patterns and attributes and AI algorithms will help you with accurate demand forecasting and reliable predictions.

Supply Chain AI Use Case 10: SKU Rationalization

When you have too many SKUs, inventory management can be a mammoth task, especially if you are using manual methods or automated means with limited capabilities. Basic software systems are also not quite up to the mark when it comes to handling excessive SKUs. SKU rationalization in such scenarios can be even more complicated.

However, the cons of not investing in SKU rationalization lead to increased warehouse costs. At times it can dilute the focus from high-performing products. If you are investing in underperforming or unprofitable products, you can miss opportunities to allocate resources to more lucrative or strategic areas.

Since SKU rationalization is a multi-layered technique, it requires agile and transformative technology like AI. This is, hence, our next supply chain AI use case.

Leveraging AI in the supply chain for SKU rationalization can:

- Help you get deeper insights into the right products with AI & ML working cohesively to recognize customer shopping patterns.

- Help you improve the portfolio management process with data-driven insights. Al algorithms help offer personalized recommendations for every outlet with detailed comparisons.

- You can identify the highest selling products faster and more effectively with updated, refined, and analyzed data in real-time. For example, segment-wise factor insights are offered based on demographics, purchasing habits, location, and local preferences.

- You will not hold onto goods that are likely to be unsold, spoil, or become obsolete, helping you reduce inventory holding costs.

- Helps in improving your warehouse management system, freeing up space and streamlining the work of your warehouse staff.

Supply Chain AI Use Case 11: Replenishment Planning

Stockouts in the global marketplace are a common thing. For some companies, optimized replenishment is never a top priority due to which they perpetually incur higher transportation costs to fulfill last-minute orders, or miss out on bulk purchasing discounts. If you are neglecting replenishment planning, you are directly hampering your competitiveness in the market.

Even if you have an effective replenishment planning strategy in place, the results may mostly be far from satisfactory. Reason: the visibility and insights into various aspects of your inventory are missing. Thus, stockouts or excess inventory are regular. So, either you are losing sales opportunities or your capital is tied up and storage costs are escalating. Either way, you need to face dissatisfied customers.

Leveraging AI in the supply chain for replenishment planning can:

- Be a big help for you to comprehend inventory trends and patterns since AI algorithms offer valuable insights into inventory levels by analyzing data from various sources.

- Mean that you have the right stock at the right time at the right place by using powerful algorithms, advanced analytics, Machine Learning, and data analytics of SaaS-based AI platforms.

- Help you optimize inventory replenishment costs with better inventory fill rates and reduced cases of excess inventory.

- Ensure that you enhance profitability, and reduce waste where advanced analytics use historical data to identify products that sell well, thereby helping optimize inventory levels,

Supply Chain AI Use Case 12: Sustainable Supply Chain Practices

We all have some responsibilities and duties towards the planet. Unfortunately, our ancestors and predecessors made some grave mistakes to exploit nature irreversibly. Some of these actions have changed the Earth forever. Thankfully, mankind can still address a few of these issues to decelerate the rate of damage.

That’s where every stakeholder in the supply chain can contribute. As per a report by McKinsey, 90% of a business’s environmental impact comes from the supply chain. Sustainable practices may require upfront investment and time, but in the long run, it becomes a habit that helps improve the planet’s condition.

Not to forget, your eco-conscious customers are going to appreciate your sustainable efforts boosting the brand image and your employees will take pride in their work. The dilemma often is how to go about the entire process. Where and with what to start?

Leveraging AI in the supply chain can

- Help you forecast demand with precision with AI algorithms that can handle huge amounts of data and analyze them optimally. This helps reduce waste and enhance sourcing.

- You can create effective transportation schedules and optimize routes with AI. This decreases fuel usage, wastage, emissions, and costs, helping reduce your carbon footprint.

- With the help of AI-based systems, datasets, advanced algorithms, predictive models, and structured information you can promote ESG objectives in the supply chain.

Conclusion

AI is fast evolving and opening up a world of possibilities in the supply chain sector. The supply chain AI use cases mentioned here are still just the tip of the iceberg. In times and years to come, you are going to hear a lot more about the transformative powers of this technology.

That said, companies will still need to actively tackle their own internal AI implementation challenges to make the most of Artificial Intelligence. From the quality of data to the right strategy and choice of technology, supply chain teams will need to set the right foundation to see results from AI.

At ThroughPut, we recommend you start with a pilot, and focus on some rapid ROI before you jump into a large-scale transformation effort. If that path resonates with you, feel free to chat with us.