Quality management is one of those things that you only realize the importance of when it does not work. When quality controls are on track, they improve efficiency and cost, and things hum along. But when they go awry, quality issues can drive up material and labor costs, threaten margins, and result in missed orders. Having a modern quality management system in place is therefore critical.

Why quality management is important

Quality management consists of the inspection and measurement of products to ensure that they meet specifications at various points along the manufacturing chain. It drives consistent quality and customer satisfaction, reduces errors and costs, improves processes and efficiency, and makes sure standards and regulations are met.

In the production process, quality management ensures that a company’s processes are designed and working as planned. An optimized process includes the production of quality products. A drop in quality can indicate a broken process somewhere along the line.

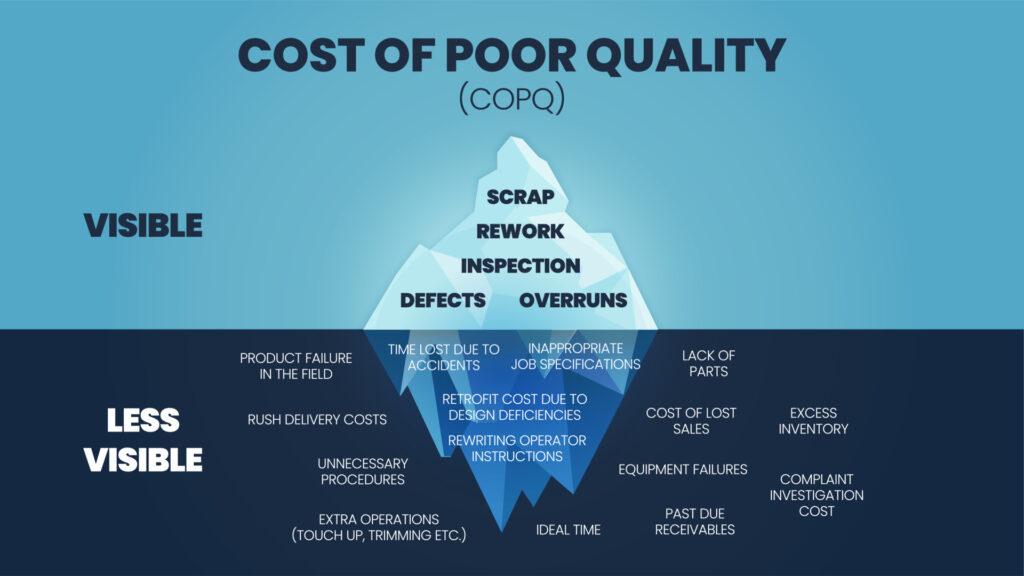

Quality management is critical to cost control. Material wasted due to poor quality impacts many of the processes along the supply chain, drives up disposal costs and can affect compliance with environmental regulations. If poor quality is not detected early, it adds additional cost at each subsequent step in the production process because of the work that has to be done or material changes required. A completed unit rejected for quality will cost a company far more than if it was identified earlier.

Then there are the hidden costs.

Finally, quality is vital to a company’s brand reputation. Poor quality can result in missed delivery times, customer dissatisfaction and the risk of losing business.

What a quality management system does

A properly functioning quality management system should ensure products and their components pass the quality criteria that have been set to uphold agreed standards. The system will track errors, keep an audit trail, issue alerts so immediate correct actions can be taken, and help identify what can be done to prevent future issues. It should also be able to evaluate suppliers’ ability to deliver to required specifications. A quality management system should keep track of changes to policies and procedures, and provide reports on anything related to the quality management process.

Focus areas of quality management

There are three areas of the manufacturing lifecycle where quality management should focus.

Materials inspection: Materials need to be checked for quality as they arrive from vendors. Predefined metrics should be established for this inspection so that a pass/fail rating can be given. A material that does not pass does not have to be returned, instead the supplier could be asked to lower the price and the material used where lower grades are acceptable. Standard checks include expiration date, strength testing or meeting weight and design specifications. If the material passes all the checks it can move to the next stage of the lifecycle.

In-process Inspection: These are checks which catch quality issues during production.

Final Inspection: This is where measurements are made of the finished goods to ensure they have been produced to specification. It may include many of the same checks used for in-process inspection.

The AQL (Acceptance Quality Limit) method can be used to check a random product sample and confirm that the risk of bad quality is acceptable. AQL identifies three categories of defects:

Critical defects: Defects that render the product unacceptable and are sent to scrap.

Major defects: Defects that are usually not acceptable by customers, and may be returned for rework.

Minor defects: Defects that are not likely to reduce the usability of the product but differ from specified standards. Some customers may accept them under concession.

Importance of digitizing quality management

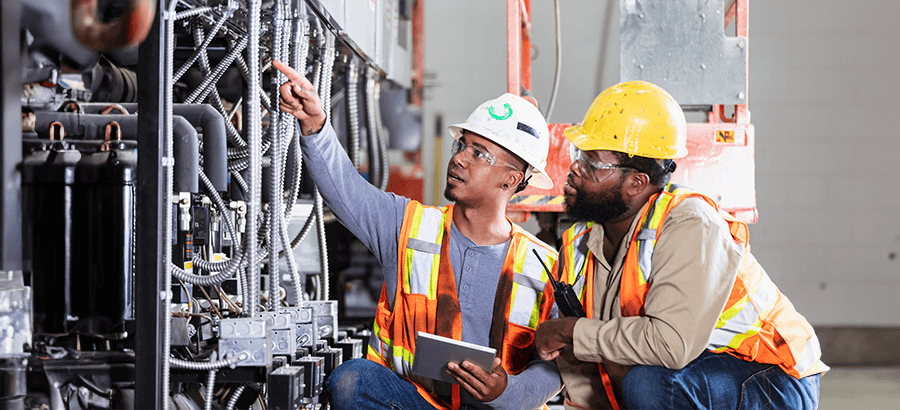

In the past, many quality control checks were done by visual inspection and relied on the inspector’s knowledge and experience. Digitizing the quality check process ensures that all the checks are done as required, are fully compliant, and real-time monitoring can enable rapid correction of quality problems when they occur.

In the production process, a smart manufacturing platform can use equipment sensors and the Industrial Internet of Things to program autonomous or semi-autonomous actions that identify problems in real time and allows rapid corrective action to be taken.

Having a digitized quality management system allows the automation of non-conformance reports so that information can be provided to inventory for inspection and manufacturing can be notified in real time.

How an ERP helps QM

Siloed departments cannot activate consolidated quality management. With the absence of an integrated workflow across departments, businesses can have multiple quality metrics and processes with conflicting goals. A quality management system as part of an integrated ERP system provides a closed-loop digital system to ensure that product quality, compliance and customer satisfaction are maintained.

An ERP system with quality management lets manufacturers implement a quality-first culture. At the inspection point, supplier quality is visible to the departments that need the information. In production, equipment performance can easily be ascertained and maintenance scheduled to maintain the quality of products

With an ERP system, the whole range of quality reporting is available to anyone with security access to see it. It enables across-the-board analytics so that recurring quality issues can be identified.

Addressing the quality challenges in manufacturing

An integrated quality management system can fix the quality challenges that manufacturers face.

- Increase communication and coordination among different departments involved in quality management to reduce errors and delays.

- Provide the tools to implement and maintain effective quality management.

- Standardize procedures to ensure consistency and accuracy across different processes, functions and locations.

- Ensure that the processes to correct quality issues can be taken, such as dealing with customer complaints or recalls.