Strategy. Strategy. Wherefore Art Thou Strategy?

Supply Chain Shaman

MAY 1, 2023

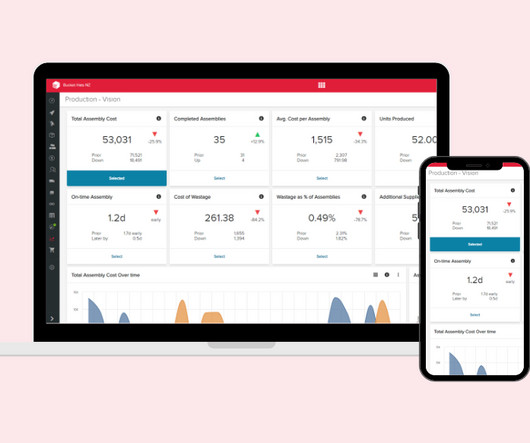

In contrast, those who outperformed were better at strategy and aligned with outcomes. Instead, the starting point, as shown in Figure 1, should start with a clear understanding of business strategy. The operating strategy–a major part of the supply chain strategy–flows from the business strategy.

Let's personalize your content